TOPIC 1

FASTENER IDENTIFICATION

Learning Outcome

Identify fasteners by specification and name the types and parts of fasteners.

Assessment Criteria

The student will correctly:

* Name the sections of a bolt.

* Name types of bolts.

* Identify parts of a thread.

* Identify bolts by grade, thread type and size.

* Name and identify types of nuts.

* Name and identify types of screws.

* Discuss the action of washers.

* Discuss torque tensioning.

TOPIC 2

FASTENER SELECTION AND FITTING

Learning Outcome

Select and fit fasteners

Assessment Criteria

The student will correctly:

* Identify fasteners on the basis of type, size, grade and thread.

* Use thread gauges to identify internal and external threads.

* Fit nuts, bolts, washers, studs and screws correctly.

* Use a tension wrench to set specified torque.

Fastener Indentification

To fasten two items together means that they are joined, and the joints are fixed or locked together. Anything which will do this is a fastener. If you consider all of the things which do this you will end up with a very long list. The most frequently used are threaded fasteners. These include bolts, screws, studs and nuts. They tend to be thought of as so common place that their limitations are overlooked. Associated with such parts are washers, snap rings, keys and cotter pins. All of the items are designed with considerable care and each is made for specific use. The importance of fasteners can be understood when you try to consider what would happen if some of these parts were to fail. Imagine what would happen to an engine if half of the bolts and nuts holding it together began to break or loosen

The weakest point in any assembly is at the fastener. It is therefore very important that you know the strength of the fastener required. The next is that the fastener is used correctly, and in the case of nuts and bolts, the most usual of mechanical fasteners, that the correct torque is applied.

The strength of such fasteners is determined by their thickness, or diameter, and by the material from which they are made. If it is required to increase the strength of a fastener, you increase its size, or choose one of the same size but made of stronger material.

Below is a diagram of some of the commonly used nuts, bolts, screws, studs and washers with which you will come in contact. You will be required to be able to identify each and understand its use

Some of the common items used to secure components - or fasten them - are described below.

Bolt

Usually not full threaded and may be fitted with a nut or screwed into a threaded hole in a component. Various head shapes are possible

Set Screws

These are similar to bolts but are fully threaded. These are sometimes known as cap screws

Studs

Studs are headless and threaded from each end. Different pitch threads may be used on each end to suit the purpose of the stud

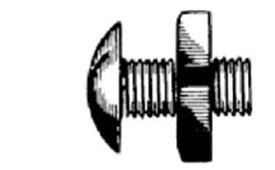

Cup Head Bolt

This round headed bolt has a part of its shank square shaped to hold the bolt. It may be used to secure timber flooring to truck bodies or for bumper bars

Metal Threads

A small diameter fully threaded screw provided with a square or a hexagon nut. The head may be round or “cheese-head” and have a screw driver slot. Metal threads are used for attaching light components or small brackets

Gutter Bolt

Fully threaded and often galvanised with a dome head and screw driver slot. The are used with a nut for securing light material and sheet metal.

Grub Screw

A headless screw which may be fitted with a screwdriver slot or a recess for an Allen key. It is used where the screw must fit below a flush surface

Self Tapping Screw

These screws will form their own thread into thin metal. There are usually used directly into sheet metal or special sheet metal nuts attached to the component. All shapes of head will be used with self tapping screws

“U” Bolts

Used to hold leaf springs to axles, and on exhaust systems

Cotter Pin

This tapered steel pin has a flat on one side and a small threaded portion on the smaller end. The flat tapered part is used to hold components such as truck king pins. A nut and washer are fitted to the cotter pin to prevent movement

Battery Bolt

A square headed bolt, heavily galvanised, is often used to tighten battery terminals to the battery posts

Taper Lock Studs

A special tap is used to produce a thread with the last few threads tapered. The stud has similarly tapered threads to create an interference fit when the stud is installed. These studs are used in particular heavy load applications on some earthmoving equipment

Plow Bolts

They have flat, tapered heads that fit into countersunk holes. When installed, the heads lie flush with the surface of the part. They are used to attach the blade to dozers and graders which require earth to roll smoothly over fastened parts.

Bolts

Because of the importance and the design of a bolt, it is important that you are able to identify its parts and functions. Look at the following diagrams carefully and learn the names of the sections of a bolt

Bolt section Names

HeadThe bolt head is formed on one end of the bolt to provide a surface for the bolt to bear on (bearing surface) and provide the means by which the bolt can be turned.

Thread Length

The length of the thread of the bolt.

Grip Length

The length which is unthreaded. Also called the shank.

Bolt length or Shank Length

The length of the bolt from the bearing surface to the end of the thread.

Bearing Surface

The underside of the head.

Point

The end of the bolt where the thread starts

Bolt Sizing

The size of a bolt is determined by three measurements.

1. The major diameter - that is the diameter at the thread end of the bolt.

2. The length of the bolt - measured from the bearing surface to the end of the thread.

3. The spanner size needed to work the bolt - the distance measured across the flats of the head.

Bolt Grading

The type of steel of which bolts (and screws) are made, and the way they are treated during manufacture determines their strength and therefore what they can be used for. This strength factor is known as the “Grade” of the fastener and is determined by the tensile strength of the bolt. That is how much pull the bolt can stand before breaking. The grade of a bolt is marked on its head. The various markings identify also identify whether the bolts is SAE (Society of Automotive Engineers) and is imperial measure, or International Standards Organisation (ISO) markings for metric sized bolts.

SAE

Grades are marked by using strokes on the head of the bolt. These range from none to eight. The following table shows how these are placed and what they mean. The table also tells you what is the tensile strength for the bolt, what it is made of, and the torque pressure which should be used, or tension, when tightening each.

The differences in the capacities of each of these emphasises the point that different grades of bolts have very different capacities. NEVER use a lower grade of bolt as a replacement. Always use the same or higher grade of bolt and tension to the same tension as the bolt it is replacing.

Tabel 1 Grafik Nilai Torsi Standar untuk Alat pengikat (fastener) Berukuran 3/8"

From this you can see that, for example, a 3/8 inch bolt with no markings is grade 1or 2. It is made of low carbon steel, would be tensioned to 20 ft/lbs (with a torque wrench) and have a minimal tensile strength of 74,000 P.S.I.

A 3/8 inch bolt with 5 strokes on the head, is grade SAE 7, is made of medium carbon alloy steel, would be tensioned to 44 ft/lbs and have a tensile strength of 133,000 P.S.I

Metric

In the same way the International Standards Organisation (I.S.O) has established standards for metric sized blots. These are given as classes which are based on strength. Marking

* numbers - on the head indicate the property class. All high quality metric bolts and screws larger than 4 mm have markings.

The following scale gives the metric grades, specifications, sizes, and SAE equivalents.

Table 2 ISO Class

Markings for steel Metric Bolts and screws

For example 4.6 indicates the class

M5 indicates - M for metric

- 5 for diameter of 5 mm 400 is tensile strength in mPa.

Written activity #2

Answer all of the following questions.

1. Name the parts of the bolt, as indicated, on the following diagram

1. -----

2. ------

3. ------

4. ------

5. ------

6. ------

7. --------

2. Complete the following table

3. If a fastener is to be replaced, what should it always be replaced with ?

-------------------------------------------------------------------------------

Threads

Threads are used extensively in the industry for the following purposes:

* Fastening - bolts, screws, studs and nuts used to hold components in position; i.e., cylinder head bolts.

* Adjustment - movement of the position of parts to provide clearances or preloads; i.e., valve (or tappet) clearance.

* Measurement - such as a micrometer.

* Movement - To convert rotary movement into linear (lengthways) movement; i.e., a vice.

Definition Of Thread Parts And Terms

In understanding the uses and manufacture of the many variations of threads in use, it is essential that certain definitions and terms be clearly understood.

Shape

Threads come in a variety of shapes, the more common being:

* Vee

* Square

* Acme

* Buttress

Vee Shape

This is the most common shape thread used on bolts, screws and studs. The actual sizes and angles will be explained later in this section

Square

The square thread is chiefly used to transmit motion in machinery.

Acme

This shape is stronger than the square and is most commonly used in the lead screw of a lath

Buttress

This thread may be used when a screw is being used to provide a large force in one direction only. Buttress threads are often used in vices

Right and heft Hand Threads

Most threads are “right hand” which means the nut is turned clockwise on to the bolt. Some special applications require the use of a “left hand” thread in which the nut is turned anti-clockwise on to the bolt

Pitch of Thread

The pitch of a thread is the distance between identical points on adjacent threads.

* On metric threads pitch is measured in millimetres.

* On imperial threads (threads measured in inches) the pitch is specified in threads per inch (TPI).

Single start Threads

A single start thread is one continuos groove which advances along the bolt. The lead and the pitch will be identical. Most bolts and studs are single start threads

Crest Diameter

The crest or major diameter is the outside diameter of an external thread on a bolt, screw or stud. The dimension of the crest diameter identifies the size of the bolt. It is measured in millimetres for metric bolts and fractions of an inch for most imperial bolts

Root Diameter

The root diameter or minor diameter is the diameter at the bottom of the thread. When tapping an internal thread the hole drilled will be the same or slightly larger than the root diameter.

Parts Of A Thread (Vee shape)

Different thread forms will have a specified shape of thread crest and root and also thread angle. The threads shown here are for an International Standards Organisation (ISO) metric thread.

Vee Thread Forms

Many thread forms have been produced by various countries and for special purposes. The following table, lists some of the Vee thread forms in use the automotive industry

When in doubt about the actual thread on a bolt or nut always measure the major diameter and the pitch (using a thread pitch gauge or a ruler) then refer to “Thread Chart” or the workshop manual

Table 3 Details of Common Vee Threads (There are many others)

Thread Pitch Gauges

Large, or coarse, threads may be measured directly with a ruler to find the pitch. The smaller or finer threads are best measured with a pitch gauge which has a number of leaves each of which has teeth of a particular pitch

Pitch gauges are available for each of the various threads such as ISO, metric, UNF, UNC, etc.

Metric ISO Coarse

Metric ISO Fine

U N F

U N F

U N C

U N C

Written Actirity #2

Answer all of the following questions.

1. Name four things for which threads are used in industry.

1. ---------------

2.---------------

3.---------------

4.----------------

2. Name four shapes of threads.

1.-------------------

2.------------------

3. ----------------

4. -----------------

3. What shape thread is most often used for bolts and screws ?

-------------------------------------------------------------------------

4. What shape thread is most often used to transmit motion ?

-----------------------------------------------------------------------

5. Which is the stronger thread - acme or square ?

-----------------------------------------------------

6. If a nut has to be turned anti - clockwise to tighten it, is the thread right or left handed ?

------------------------------------------------------------

7. What unit do you use to measure the pitch of a metric thread ?

--------------------------------------------------------------------------

8. How do you specify the pitch of an imperial thread ?

------------------------------------------------------------------------

9. What does the outside diameter of a thread, or a bolt give you ?

---------------------------------------------

10. What is the unit in which bolt size in measured ?

Metric measure -------------------------------

Imperial measure ------------------------------

11. If you are tapping an internal thread, what will the diameter of the hole drilled be the same as ?

------------------------------------------------------------------

12. What would you use to measure the pitch of a thread ?

-------------------------------------------------------------------

Nuts and Washers

There are various types of nuts. Most are hexagonal (six sided) but square nuts are sometimes used.Plain Nut

The most usual is a plain nut. It is hexagonal in shape and is smooth on both sides. Therefore it requires some type of lock washer or nut to prevent it from coming loose on the stud or bolt

Castellated Nuts

A split pin is used through a hole in the stud or bolt and the slots of the nut. The split pin must be of sufficient diameter to fit easily through the hole without excessive clearance. A new split pin must always be used each time the nut is re-fitted.

Lock Nut

The nut is thinner than a standard nut and is screwed onto the bolt on top of the normal plain nut. The tightening of the lock nut stretches the bolt thread slightly preventing the plain nut from loosening.

Self Locking Nuts

These nuts are of many types. A common example uses a piece of fibre or plastic material to grip onto the bolt or stud to prevent movement

Pal Nut

The pal nut is a pressed sheet metal locking device which is lightly tightened down onto the securing nut to lock it in place. Similar types of pressed metal fasteners are often used with self tapping screws

Lock Washers

These are compressed under the nut or bolt head to provide a springing effect which prevents the nut or bolt from loosening

Locking Wire

In some applications the heads of the bolts or set screws are drilled to allow a soft piece of wire to be threaded through to prevent the bolts loosening

Locking Plates and Tag Washers

Locking plates are re-usable devices which are secured to the component in such a way as to prevent movement of the bolt or nut.

Tag washers are placed under a bolt or nut and the tags bent in such a manner as to prevent movement. Tag washers should be replaced once disturbed.

Screws

A number of different types of screws are used in the manufacture of equipment and each performs a particular function. Some of these and their uses are described below.

Screws used for securing metal parts are threaded right up to the head. The heads have various shapes, with different types of slots or recesses for driving the screw. Special screwdrivers or spanners are required for the special screw heads.

Certain bolts with hexagonal heads are also threaded for their full length and classed under the broad heading of “screws”. These may be referred to as set screws in particular locations. The point or ends of screws are also made in various shapes for particular purposes

Various types of screw heads

Written Actirity #3

Answer all of the following questions.

1. What is the name of a nut which has slots cut in it to lock it?

----------------------------------------------------------

2. What do you call a nut which uses a piece of plastic to prevent it from becoming loose?

-----------------------------------------------------------

3. What are washers used for?

---------------------------------------------------------

4. Name three types ofscrews

a. ----

b. -----

c. -----

FASTENER TORQUE AND TENSION

Torque is basically the amount of twisting action at a given point. Without some way of measuring torque, it is impossible for any mechanic to tighten a series of bolts, nuts or screws to an exact, predetermined tension. This is why torque wrenches must be used

With today’s modern machinery, which uses many new and different kinds of light alloys (an alloy being a mixture of two or more metals), torque of bolts, nuts and screws becomes a very critical operation. Applying too little torque will cause leaks (liquid or gas). Applying too much torque will cause leaks too, but will also cause distortion and major damage to expensive parts

Consider the cylinder head bolts on an engine. Every time the fuel ignites, the cylinder is subject to a great pressure - often a total force of 50,000 pounds (222 400 N) can be pushing up on one side of the head at peak cylinder pressure. If the bolts are not tensioned (stretched) when installed, the pressure will cause them to stretch. They will then relax and shrink to normal length when the pressure diminishes. This constant stretching and relaxing will lead to metal fatigue and eventual failure.

If a fastener is correctly tensioned the force applied to it by the load cannot stretch the fastener. In this way the fastener is not continually stretched and therefore will not be subject to fatigue failure

Tension Wrench

A tension wrench, sometimes called, a ‘Torque Wrench’ acts as a torque-limiting device for turning nuts to a predetermined degree of tightness. This prevents the breaking of fasteners. In many cases it is essential to use a Torque Wrench to avoid warping or springing of components held by multiple fasteners which could be unevenly or excessively tightened - cylinder heads of engines, for example

Some Torque Wrench have direct -reading indictors that you must watch as you pull the handle to the desired extent. With other Torque Wrench you preset them to the desired graduation and pull until you detect a signal, which may be an audible click, the release of a trigger pin, or an automatic release within the wrench mechanism

Tension Wrench Use

To use a Torque Wrench correctly the following points must be observed:

Force application must be smooth. A steady force is applied to the Torque Wrench handle to obtain accurate torque values. Exerting rapid or jerky force can result in considerable error in the torque applied

With a Deflecting Beam Torque Wrench (A), the torque value is read on the scale (B) as the force is applied to the handle

* With a Dial Torque Wrench (C), the dial (D) must be rotated and placed on zero before applying any force to the torque wrench handle. Sometimes the dial will then be in a poor position to be read, so if the Torque Wrench has a dial which rotates both clockwise and counter clockwise, set the dial at the predetermined torque value rather than zero and apply force to the handle. The indicator pointer will travel from the predetermined torque value back to zero.

With an Audible Click Torque Wrench (E), preset the torque value on the wrench by releasing the lock (G) on the handle and rotating the “micrometer” barrel (H) clockwise or counterclockwise to the desired torque setting (F). The lock must be relocked once the setting has been made

Thread hubrication

Threads of fasteners must be clean and free of nicks, burrs, paint or heavy grease to obtain the correct torque value. A good lubricant or anti-seize compound should be used on the threads prior to installing the fastener. Light oil or graphite-type lubricants work just fine

Thread Damage

Studs, bolts or nuts with damaged threads should be replaced or a new thread cut. If you feel you can succeed in installing a nut on a damaged thread or a damaged bolt or stud in a hole, you must take into account not only possible damage to the parts you are assembling but the added rundown or tightening resistance you will encounter, which will give a wrong torque setting

Pre-torqued Fasteners

An accurate check of already-tight fasteners to determine if they have been tightened to a specific torque value is not possible. A fastener that has been tightened to a specified torque value requires approximately 10% more torque than was originally applied to overcome friction and start the fastener turning again. When there is doubt as to whether a fastener has been tightened to the correct torque value, it should be loosened approximately 1/2 to 1 full turn and retorqued to the correct torque value.

Fitting a Cotter Pin

When aligning for cotter pins, never loosen the castellated nut (A) to obtain hole alignment on a stud or bolt (B). When a nut is to be secured to a stud or bolt with a cotter pin (C) or safety wire, the nut should be tightened to the low range of the desired torque value and the hole aligned by further tightening the nut

Nut and Bolt Tensioning

When a bolt is torqued from the head end, some of the torque applied is absorbed in turning the bolt in the hole. The amount of torque absorbed varies, depending on the clearance in the hole and the alignment of the parts. For this reason, torque values are given for tightening bolts on the nut end. If an occasion arises when the nut end on a bolt cannot be reached with a torque wrench and the bolthead must be torqued, the bolt should be tightened to the high range of the torque value desired while holding the nut end securely with some type of wrench.

Tensioning Sequence

To properly torque a series of fasteners, they should be torqued in a specific way. This will apply even pressure on the mating surfaces of the parts being torqued. Never torque two mating surfaces (such as cylinder heads) by following the bolt pattern clockwise or counter clockwise.

Note

Always check and follow the manufactures specifications.

Tension Procedure

All fasteners should be screwed down until they are incontact with surface they are holding down first, then brought up to the desired torque value in stages of 20%, 40%, 60%, 80% and then full torque. (This means the percentage of the total desired torque value). For instance, if the desired torque value is 250 inch-pounds, then 20% of 250inch-pounds would be 50 inch-pounds. 60% of 250 inch- pounds would be 150 inch-pounds, and so on until full torque value is reached.

Sometimes a set or seizure will occur while tightening a fastener. This is indicated by a popping effect during the final stages of tightening. When a seizure occurs, back off the bolt or nut and retighten it with a steady

sweep of the wrench handle. Take the torque reading while the wrench is moving

Tension wrench scales

There are two main scales used for tension wrenches:

* Imperial: foot pounds expressed on the tension wrench scale as ft lbs.

* Metric: newton metres expressed on the tension wrench scale as Nm.

Imperial

Lever length measured to one foot, with a force acting at the one foot mark of one pound.

Metric

Lever length measured to one metre with a force acting at the metre mark of one Newton

Care of torque tools

A Torque Wrench is a precision instrument and must be handled with care. Torque Wrenches should never be carelessly tossed among other tools but should be stored in a clean dry place. With Deflecting Beam Torque Wrenches the frame is the measuring element and should never be altered in any way such as, filing, etching or stamping. Permanent damage will result

Unified Inch Bolt and Cap Screw Torque Values

DO NOT use these values if a different torque value or tightening procedure is given for a specific application. Torque values listed are for general use only.

* “Lubricated” means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coatings. “Dry” means plain or zinc plated without any lubrication.

* Grade 2 applies for hex cap screws (not hex bolts) up to 152 mm (6-in.) long. Grade 1 applies for hex cap screws over 152 mm (6-in) long, and for all other types of bolts and screws of any length.

Fasteners should be replaced with the same or higher grade. If higher grade fasteners are used, these should only be tightened to the strength of the original.

Make sure fasteners threads are clean and that you properly start thread engagement. This will prevent them from failing when tightening.

Tighten plastic insert or crimped steel-type lock nuts to approximately 50 percent of the dry torque shown in the chart, applied to the nut, not to the bolt head. Tighten

toothed or serrated-type lock nuts to the full torque value

Metric Bolt and Cap crew Torque Values

Fasteners should be replaced with the same or higher property class. If higher property class fasteners are used, these should only be tightened to the strength of the original

* “Lubricated means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coating& “Dry means plain or zinc plated without any lubrication.

Make sure fasteners threads are clean and that you properly start thread engagement. This will prevent them from failing when tightening.

Tighten plastic insert or crimped steel-type lock nuts to approximately 50 percent of the dry torque shown in the chart, applied to the nut, not to the bolt head. Tighten toothed or serrated-type lock nuts to the full torque value.

Written Actirity #4

Answer all of the following questions.

1. What is the name of the tool used to set the tension of a nut or bolt ?

-----------------------------------------------------------------------------------

2. What would be the result of applying two little torque to bolts or nuts?

----------------------------------------------------------------------

3. What effect does torquing have on a bolt?

------------------------------------------------------------------

4. What happens if a bolt or nut is not properly torqued?

------------------------------------------------------------------

5. What is likely to happen if you apply a jerking force to the handle of a Torque Wrench ?

---------------------------------------------------------------------

6. What is likely to cause the incorrect tensioning of bolts or nuts ?

---------------------------------------------------------------------------

7. What are the two scales found on torque wrenches ?

--------------------------------------------------------------------------

KEY ANSWER FOR WRITEN ACTIVITY

Writen activity 1

Answer all of the following questions.

1. Name the parts of the bolt, as indicated, on the following diagram.

1. Head 5. Shank or Grip length

2. Flat 6. Thread lenght

3. Bearing face 7. Bolt size or diameter

4. Length

2. Complete the following table

3. If a fastener is to be replaced, what should always be replaced with ?

A fastener of the same category.

Written Actvity.2

Answer all of the following questions.

1. Name four things for which threads are used in industry.

1. Fastening

2. Adjustment

3. Measurement

4. Movement

2. Name four shapes of threads.

1. Vee

2. Square

3. Acme

4. Buttress

3. What shape thread is most often used for bolts and screws ?

Vee

4. What shape thread is most often used to transmit motion ?

Square

5. Which is the stronger thread - acme or square ?

Acme

6. If a nut has to be turned anti - clockwise to tighten it, is the thread right or left handed ?

Left.

7. What unit do you use to measure the pitch of a metric thread ?

Millimeters

8. How do you specify the pitch of an imperial thread ?

Threads per inch

9. What does the outside diameter of the thread of a bolt give you?

Bolt siz

10. What is the unit in which bolt size in measured?:

Metric : measure millimeters

Imperial: measure fractions of an inch

11. If you are tapping an internal thread, what will the diameter of the hole drilled be the same as?

Root diameter

12. What would you use to measure the pitch of a thread ?

Thread Gauge

Writen Activity 3

Answer all of the following questions.

1. What is the name of a nut which has slots cut in it to lock it ?

Castellated

2. What do you call a nut which uses a piece of plastic to prevent it from becoming loose ?

Self locking

3. What are washers used for ?

Prevent the nut from becoming loose

4. Name three types of screws.

1. Grub

2. Set

3. Phillips

Written Actirity #4

Answer all of the following questions.

1. What is the name of the tool used to set the tension of a nut or bolt ?

Torque Wrench

2. What would be the result of applying two little torque to bolts or nuts?

Metal Fastener

3. What effect does torquing have on a bolt?

Wrench Fastener

4. What happens if a bolt or nut is not properly torqued?

Fastener

5. What is likely to happen if you apply a jerking force to the handle of a torque wrench ?

Incorrect torque applied

6. What is likely to cause the incorrect tensioning of a bolt or nuts ?

1. Jerking action on Torque Wrench

2. Faulty thread, 3 dirt, nut or green on thread

7. (1.28) What are the two scales found on torque wrenches ?

1. Imperial - Ft./Lbs.

2. Metric - MN.

THANK YOU HAVE VISITED ON WWW.GOSGT.COM

FASTENER IDENTIFICATION

Reviewed by heri

on

3:02 PM

Rating:

Reviewed by heri

on

3:02 PM

Rating:

Reviewed by heri

on

3:02 PM

Rating:

Reviewed by heri

on

3:02 PM

Rating:

No comments: