VITAL INFORMATION MANAGEMENT SYSTEM

INTRODUCTION

INTRODUCTION

This Technical Instruction Module discusses the Vital Information Management System (VIMS). The system operates on different machine models, and all components discussed in this presentation may not be present on every machine. When uploaded with source code software, the VIMS main module recognizes (through configuration software) the machine on which it is installed and, therefore, knows which components are present.This presentation covers the basic system operation, major and related components, onboard and offboard applications, and hardware/software requirements of the system. This training package is intended to be basic and will be referenced as a prerequisite for other machine specific VIMS applications.

System features

The Vital Information Management System is an electronic monitoring system for large Caterpillar machines. The system is composed of modular onboard electronics which have the ability to acquire data, perform analysis, store informatian and display data.Using both onboard and oftboard hardware and software, the VIMS displays information to the machine operator in addition to supplying information on machine systems to dealer and customer technical staff. This information will assist in minimizing downtime and operating costs.

The various electronic modules that compose the VTh1S communicate with each other in addition to receiving information from other machine electronic controls (such as the engine control, transmission control, etc.).

To successfully service machines equipped with the VTh1S, the serviceman needs to become proficient in accessing the information through the onboard keypad and message center, and must also be able to use a service tool (PC) to perform other required tasks..

SYSTEM OPERATION

The VIMS is designed to alert the operator of an immediate or impending abnormal condition in one or more"'f the machine systems that are being monitored. These abnormal conditions are called "events." Two types of events are recognized and stored by the VIMS. One event is called a "MACHINE" event and alerts the operator to an abnormal machine condition (such as hydraulic temperature too high). The other event is called a "SYSTEM" event which alerts the operator to a fault condition which is caused by a malfunction (fault) in one of the electronic devices (such as hydraulic temperature sensor being used to monitor a machine system). A more detailed explanation of "events" will be covered later in the module.In addition to alerting the operator of an abnormal condition, a service lamp is installed externally on the machine to alert service or maintenance personnel that an "event" is present and diagnostic information regarding the event is available in the VIMS.

The major modules that comprise the Vital Information Management System will now be discussed in detail..

Major Components

Gauge Cluster ModuleThe gauge cluster module contains four gauges to provide information on measured machine parameters (such as temperature, pressure, and fuel level). Consult the appropriate Operation and Maintenance Guide for specific machine parameters.

The VIMS uses electronic input devices (sensors) to measure the parameter, calculates an output signal and sends the signal to the gauge cluster where the parameter is displayed.

The gauge cluster is configured for a specific machine (shovel, off highway truck or wheel loader) and the actual machine parameter is represented on the gauge by a graphic symbol.

Speedometer /thachometer Module

The speedometer/tachometer (not used on all machines) displays ground speed in mph (kmlh), engine speed,..and transmission actual gear position. The electronic input devices used for this information will be discussed later..

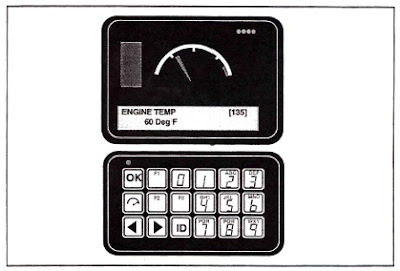

Message Center Module

The message center module contains a Data·Logger indicator, alert indicator, universal gauge, gauge warning area and message area.The Data Logger indicator (series of four dots) in the upper right comer scrolls when the Data Logger is turned on. The dots are not present when the Data Logger is stopped or when the Data Logger is initiated with the offboard service tool (PC).

The alert indicator notifies the operator of an abnormal machine· condition. The condition could be caused by the VIMS detecting a ":{Il.achine" or "system" event. The alert indicator receives a signal from the main module causing the indicator to flash. The alert indicator will be discussed in detail in the warning operation section of this presentation.

The message area shows the value for the parameter shown on the universal gauge. For sensor-type parameters (non switch-type inputs), the gauge shows the actual value for the parameter being measured. The gauge can also be used to observe any of the machine parameters by entering the parameter number on the keypad and pressing the "gauge" on the keypad. The universal gauge allows the operator or serviceman to select their "favorite" parameter or to monitor a troublesome parameter which has not exceeded its limit.

The message area displays information regarding the condition of the machine. The display of information is prioritized and includes ( 1) machine or system events, (2) operator or serviceman requested data, and default information

The message area provides two lines of text (twenty characters each line) to display information to the operator or serviceman. When an event (machine or system) occurs, information relating to the out-of specification parameter is displayed on the first line to identify the nature of the abnormal condition. The following is an example of information that may appear in the message area if an abnormal machine event occurs.

LOW ENGINE OIL LEVEL SHUT DOWN SAFELY

Information on the second line displays the desired operator response to the condition.

If a system event occurs, the message area will display the parameter followed by the word ERROR. The second line will give the operator instructions regarding the condition. The following is an example of information thatJilllY appear if a system event is active.

OIL PRESSURE ERROR.

CALL SHOP

If more than one event is present at a time, the event information will be displayed according to priority. The priority process will be discussed in the warning operation section of this module.

The message area can also display requested data such as event lists or active system events in Module Identification (MID), Component Identification (CID), and Failure Mode Identifier (FMl) format.

If no data has been requested by the operator and no event messages are active, default information will be presented in the message area. The default information includes time of day and machine service hours. The following is an example of default information displayed in the message area:

0745 267

If a problem exists in either the source code or configuration software, the time of day and service meter hours will not be displayed after start-up.

Keypad

The keypad allows the operator or serviceman to communicate with the VIMS by entering numeric information. The numeric section of the keypad (keys 0 - 9) can be used to initiate service procedures, enter operator identification codes, acknowledge events, and respond to VIMS queries (such as data logging information).An indicator (upper left corner of keypad) flashes each time a key is pressed to inform the operator or serviceman that the keystroke was accepted.

Six additional keys are available for inputting information. They are:

Key OK : Used to complete keypad entries and to acknowledge events.

Key ID :Used by the operator to enter his/her identification or badge number into the VIMS memory.

Key parameter ,Used to display the value of any measured parameter. When the gauge key is pressed, line one of the message area displays the parameter name and parameter number, and line two displays the parameter value and unit of measure.

The information displayed using the gauge key is presented for one parameter at a time. To scroll through the remaining parameters requires using the Forward and Backward arrow keys.

A specific parameter can be displayed without using the forward/backward keys by entering the number of the parameter and then pressing the Gauge key. The requested information will remain displayed until the OK key is pressed, which returns the message center module to the default mode .

If an event occurs while a parameter is being

displayed, the parameter information will be overwritten with the event information..

Key more or less than: ,Allow operator or serviceman to scroll forward or backward through the information shown in the message area.

Key F1: ,Allows the operator or serviceman to request additional information regarding machine and system events. If a machine event is displayed, pressing the Fl key will replace the information shown on line two of the message area with the event value and units (example: 84 psi).

If a system event is displayed, pressing the Fl key will replace the information shown on line two with MID, CID and FMI information (example: MID 049, CID 0168, FMI 04).

Key F2 and F3: ,Not used at this time

Main VIMS Module

The main module is the "heart" of the VIMS and, as such, makesdecisions based upon inputs received from various other electronic control modules on the machine. A 37 pin connector on the module connects the necessary harness wiring to the input and output devices.

The overall function of the main module can be described in four sections. The four sections are labeled: Data Links, Inputs, Outputs and Display Components.

Data Links

The main modules incorporate four different data links. One is the CAT Data Link which is a bi-directional link allowing the VIMS to communicate with other onboard electronic controls. The CAT Data Link uses two communication paths to ensure uninterrupted communications in the event of an open in one path.

The second and third data links are RS-232 data links. These two communication links are separate. One of the links has two communication ports, one .in the cab and the other mounted outside the cab to allow easy access for the serviceman.

The second RS-232 Data Link allows the VIMS to communicate with an offboard service tool (PC).

The third RS-232 Data Link allows the VIMS to communicate through two-way radio communications with other offboard systems.

The fourth Data Link is an instrumentation link that connects the various display components to the main module.

Inputs

Inputs to the VIMS main module include a switch type input from the key start switch, open or grounded switch-type inputs from switches used to monitor machine events, a lighting sensor to inform the main module when the dash panel lamps are turned ON, a keypad input to receive information from the keypad , and an input "that measures system voltage at the VIMS circuit breaker.

Outputs

The main module sends an output signal to the

action lamp if a Category 2 or 3 warning is present. The module also sends a signal to the action alarm to sound an alarm if a Category 3 warning is present. The main module provides power for all the display components, and turns a service light ON (steady) to alert maintenance personnel if an active system event is present. The light will flash if an abuse related event is present.

Display component

The main module supplies information to all the display components (gauge cluster, speedometer/tachometer, message center and keypad). The display components alert the operator to machine conditions.

Interface Module( s).

The VIMS can accommodate up to eight interface modules. The exact number of interface modules installed on a Caterpillar machine will be determined by the configuration software. Although each module functions in the same manner, each module will be assigned its own individual MID. The MID number associated with each module is determined by the machine harness code connections on each module.The interface modules receive inputs from the sensors and switc es, process the information and then send an output to the J.?ain VIMS module over the CAT Data Link where the information is processed and sent to the various display components.

Interface modules are placed in close proximity to their input devices and use the Data Link to provide input to the main module. This proximity greatly reduces the amount of wiring harnesses that would normally be required to send each input signal to a central location.

Each interface module operates as a separate electronic control and contains identical internal components. Each module has the capacity to process eight pulse width modulation (PWM) inputs, nine switch (on-off)

inputs, and three frequency (speed/pressure) inputs.

The following is a brief description of the interface module inputs:

Sensor Inputs

The VIMS uses sensors to provide information on the various measured parameters. The sensors used by the VIMS are either pulse width modulation or frequency type. The physical operation of the sensors will be discussed later in this module.

Switch Inputs

Each module is capable of processing information trom thirteen switches. Eight of the switch inputs are uncommitted and provide the module with machine system status information (open or grounded). The information is received from pressure switches, temperature switches, flow and level switches and position switches.

One switch input is a committed input received from the key start switch and provides the module with battery voltage on contact No. 1 of the 40 pin connector when the key switch is in the ON position. •

The remaining four inputs are programming type inputs and, as such, are harness code inputs that tell the main VJ¥S module which interface module it is communicating with. A combination of grounded and open harness code inputs determines the unique MID code for each module installed on the machine.

CAT Data Link

This Data Link provides the VIMS with both an input and output. Its primary purpose is to provide a high speed ring that allows data to be shared by all electronic controls used on the machine. Each VIMS module has two identical Data Links that work independently. The two communication paths allow the VIMS to continue operating even if one of the Data Links becomes damaged. The CAT Data Link system is bi-directional (input/output) and also performs as an output device.

The interface module(s), in addition to receiving and processing information from individual electronic devices (sensors and switches), provide outputs. The primary outputs are delivered via the CAT Data Link to the main VIMS module. The interface module does provide two solenoid outputs which can be used to energize solenoids or relay coils, and also provides two regulated voltage outputs that are used to power the sensors. The regulated outputs are +8 and +5 DCV.

Other Modules

Depending on the machine configuration and software, numerous other modules can be connected to the VIMS. Some of the other electronic control modules that may be installed are:

Electronic Unit Injection (engine control)

Electronic Programmable Transmission Control (EPTC II)

Automatic Retarder Control (ARC)

Each additional control module processes its own input devices and uses

the CAT Data Link to communicate with the VIMS

MESSAGE CENTER AND KEYPAD

In addition to supplying the operator and serviceman with machine and system event information , the message center and keypad can be used to initiate numerous VIMS service operations.Service Operations

This section will cover those service operations that directly impact operator or service technician areas of responsibility. A more detailed explanation of the service operations and codes can be found in the appropriate machine service manual module(s). The service operations and codes are specific to machine applications.

To enter a service operation, the operator or serviceman must enter a numerical or alpha code into the VIMS using the keypad. The numerical code assigned to each service operation can be up to eight digits. The digits are associated with the numeric keypad and represent numbers from two to nine. Also, the corresponding alpha characters associated with

each key can be entered. The following is an example of a service

program code:

35478

Numerical digits assigned to the service program for viewing the event list.

ELIST

Alpha letters associated with the digits 35478 on the keypad

In the assignment of service program codes, the numerical code is a direct correlation to the letter code in English only. The alpha (letter) designator is used to simplify (easier to remember) the coding system. After

entering a service program code, the OK key on the keypad must be pressed to initiate the entry.

The following is a brief description of each service program code and its operation.

3564 (DLOG)

Starts and stops the Data Logger. When the Data

Logger is operating, the four indicator dots in the upper right corner of the universal gauge begin scrolling. When the Data Logger is turned ON, the storage time remaining will be displayed in the message center for five seconds. The Data Logger can also be turned on by using an offboard service tool (PC). lf a PC is used to initiate the scrolling, the indicator dots will not be shown.

35737 (DLRES)

Resets the Data Logger storage time to 30 minutes.

Any information currently in the Data Logger memory will be erased when this program service code is initited.

3225 (EACK)

Allows viewing of all active events that have been

acknowledged but not corrected.

35478 (ELIST)

Allows viewing of machine and system events.

Events will be displayed on a "last in - first out" basis. The FORWARD and BACKWARD arrow keys can be used to scroll through the event list. When the "oldest" event is displayed, the message center will indicate that the "end of the list" is reached.

HYD OIL LEVEL IDGH

527 000:05:2

Machine events will display the following information in the message area in the following format: parameter name, event status, service meter reading when event began, and the duration.

Example:

If the Fl key on the keypad is pressed while viewing the preceding information, the parameter value and units will be displayed on the second line of the preceding message.

System events will display the following information: parameter name, Error, service meter reading when event began, and the duration of the event.

Example:

Oil Pressure ERROR

465 000:06:56

If the Fl key on the keypad is pressed while viewing the above information, the MID, CID and

FMI diagnostic information will be displayed on the second line of the above message.

3732 (EREC)

Turns ON the event recorder. When the event recorder is initiated, all parameter values are

stored for the previous period of five minutes before the event occurred and continues for one

minute following the initiation. This information is primarily us d by management or technical personnel for diagnostics and requires the use of

an offboard service tool (PC).

The event recorder can only be initiated a maximum of two times before downloading the stored information. The capacity of the onboard recording system is limited to two recordings. Also, clearing the event recorder is permitted only after the information stored is downloaded with a service tool (PC).

37828 (ESTAT)

Displays the number of machine and system events stored since the main VIMS module was last cleared. Example:

EVENTS SYSTEM 005

MACIDNE 047

52 (LA)

Allows the information to be displayed in two different languages. The display can be toggled between two of the available programmed languages. (Available languages are determined by the configuration software.).

582626 (LUBMAN)

Allows for manual override of the automatic lube system and begins one auto lube cycle. (Auto lube is not installed on all machine models .).

582738 (LUBSET)

Used to set the time interval between each lubrication and the cycle repetition rate. The lube duration is machine specific (check the appropriate service literature) .The message center will display the Auto Lube repetition rate in seconds on the first line and the time in seconds on the second line. Use the FORWARD and BACKWARD arrow keys to adjust the cycle time. Press the OK key to set the cycle interval.

782548 (SVCLIT)

Allows the operator to reset the service light for only the event displayed in the message area.

86 (UN)

Allows the displayed information to be toggled between U.S. and Metric units of measure.

The service program codes listed above are common to all current Caterpillar products with the VIMS installed. The following list of service program .codes are specific to the Payload Measurement System on large off-highway trucks (785B, 789B and 793B) equipped with the VIMS.

729225 (PAYCAL)

Operator or serviceman initiates the PAYCAL service program code whenever it is necessary to calibrate the Payload Measurement System.

868 (TOT)

Displays total haul cycles, shift payloads, etc.

73738 (RESET)

Resets payload totals, haul cycles, etc. (only while viewing the information).

For specific detailed information, consult the appropriate service manual for the Truck Payload Measurement System (TPMS)

Warning Operation

The VIMS monitors designated machine systems and notifies the operator of immediate or impending problems. The warning categories of the VIMS are the same as those used with the Computerized Monitoring System (CMS). The inputs and internal operation of the controls differ, but the outputs of the system remain unchanged.The operator receives the following types of warning:

Warning Category 1

Alert indicator flashes. No immediate action required by the operator. (Requires servicing by the end of the shift.).

Warning Category 2

Alert indicator flashes and the action lamp flashes. Machine operation should be changed or maintenance performed.

Warning Category 3

Alert indicator flashes, action lamp flashes and action alarm sounds. Operator should perform an immediate safe engine shutdown

The VIMS triggers the warning operation when a machine or system event occurs. The abnormal condition is sensed by the interface module, processed, and then sent to the main module where the appropriate warning category is determined and relayed to the operator through the alert indicator (flashing), action lamp (flashing) or the action alarm (sounding).

Warning inputs are pro_vided by switches and sensors. In some cases, more than one input is needed to trigger a specific warning category. The VIMS identifies the warning category displayed according to active events. If more than one event is active, each event will be scrolled on the message area in five second intervals. If a warning Category 3 (most severe) event is active, Category 1 and 2 events cannot be scrolled.

Although the VIMS warning categories are the same as those used on other systems (EMS and CMS), some changes have been made in the area of operator awareness. The VIMS documents when the operator acknowledges the fault. When a Category 1 or 2 event becomes active, the operator can acknowledge the event by pressing the OK key on the keypad. Depending on the nature of the event, the warning category may be cancelled for a specific period of time. After the time interval is exceeded, the warning category will again be displayed. Category 3

events cannot be cancelled by the.operator.

NOTE: The above information is general in nature. For spe ific machine information, consult the appropriate Operation and Maintenance Manual for the machine in question.

Parameters

Each machine system being monitored will have a parameter name and identification number. The parameter name will be easily identifiable by the operator and not all parameters will be present on all machines. Consult the appropriate Operation and Maintenance Manual for the machine in question.Each parameter will have a specific predefined warning limit. If a switch type input is being used to monitor a specific machine parameter. the actuation (open or closing) of the switch contacts will trigger a warning category. If a sensor is being used to monitor a specific machine parameter. the warning category will be triggered when the data being diagnosed reaches a predetermined limit (out-of-range high or low).

The procedure for viewing machine parameters will discussed in detail later in this module.

ONBOARD APPLICATIONS

The VIMS onboard components not only display information relating to machine parameters but, as stated earlier, also alert the operator of an impending event (abnormal condition) in one or more of the machine systems being monitored. These abnormal conditions are called "events." There are two categories of events: machine events and system events.Machine events indicate that the machine is operating outside of normal limits. A machine event may occur because a specific parameter detects an abnormal condition. An example of a machine event could be low hydraulic fluid level or low fuel level. The VIMS will alert the operator via the appropriate warning category. The operator must acknowledge the event and then take the appropriate action required. If more than one event is present of the same category, the message center will alternate between each event.

System events reflect the VIMS self-diagnostic capabilities. If the VIMS detects an event condition in one or more of its electronic monitoring devices (switches, sensors, etc.), a system event will be immediately displayed on the message center and the operator will be alerted by the appropriate warning. The serviceman can retrieve additional diagnostic information on the detected fauit by pressing the Fl key on the keypad or by accessing the VIMS through the use of a service tool (PC).

Machine Events

The message area provides two lines (twenty characters each line) to display information to the operator..or serviceman. When a machine event occurs, a message is displayed on the first line to identify the nature of the abnormal condition. The second line indicates the required operator action.VOLTAGE TOO LOW

SHUT DOWN SAFELY

In the above example , the operator is alerted to a Category 3 warning. The alert indicator and action lamp will flash and the action alarm will sound. The message center directs the operator to shut the machine down safely.

The VIMS detected a critically low system voltage (less than 23.0 volts). Continued machine operation with low system voltage could possibly cause the electronic controls installed on the machine to shut down.

The serviceman can easily investigate the machine event using the universal gauge as a service tool. Entering the parameter number of 140 and pressing the gauge key on the keypad will display the parameter name and number on the first line and the parameter value and units on the second line. Example:

VOLTAGE (140)

22.5 VOLTS

Troubleshooting Machine Events

When a machine event occurs and the serviceman is requested to diagnose the malfunction, it is important that all the facts concerning the reported complaint are gathered. The advanced capabilities of the VIMS

allow the system to distinguish between actual problems with the machine or its components and conditions caused by inappropriate operation (abuse). The VIMS will distinguish between the types of problems and maintain a count of occ.urrences in memory.

To effectively diagnose machine events may require the serviceman to use all available VIMS resources. The message center and keypad may be used to display event information such as event statistics, event list and acknowledge events. To observe the above information, the serviceman must initiate the appropriate service operation.

Also, the event information can be downloaded using a service tool (PC) to access the VIMS. Downloading an event list will provide the serviceman with the following types of event information:

• Machine serial number

• Service Meter Units (SMU)

• Description (event name)

• Date of event

• Time event started

• Minimum or maximum limits (value where a warning occurs)

• Units of measurement

• Actual event value

• Event duration

• Acknowledgment time

It may also be necessary to use other types of stored information in solving machine abnormalities. For a more detailed explanation of other available resources, consult the offboard service tool documentation.

System Events

The message area provides two lines (twenty characters each line) to display information to the operatol"or serviceman. When a system event occurs, information identifying a specific parameter has "error" displayed on the first line and information giving the operator instructions appears on the second line. Example:OIL PRESSURE ERR

CALL SHOP

With the above information displayed in the message area, additional diagnostic information can be displayed on the second line by pressing the Fl key on the keypad. The display will now show the MID, CID and FMI codes for the active system event. Example:

OIL PRESSURE ERR

MID057 CID0827 FMI00

The diagnostic codes displayed on the second line provide valuable information to the serviceman. The MID identifies which electronic control has diagnosed the event. Since the VIM:S has the ability to receive system event information from other controls over the CAT Data Link, it is necessary to establish the source of the event. Each electronic control module installed on the machine has its own unique identifier. The following list identifies the module

MID MODULE.

027 Transmissi Control ( jika terpasang )

036 Engine Control .

049 VIMS Main Module.

057 Interface Module No.1

058 Interface Module No.2.

059 Interface Module No.3 ( jika dipasang ).

060 Interface Module No. 4 ( jika dipasang )

065 Interface Module No. 5 ( jika dipasang)

066 Interface Module No. 6 ( jika dipasang )

067 Interface Module No. 7 ( jika dipasang ).

068 Interface Module No. 8 ( jika dipasang)

083 Automatic Retarder Control (Jika dilengkapi)

Each electronic control system (VIMS, Ell, EPTC II, ARC, etc.) installed on Caterpillar machines uses numerous sensing devices to provide inputs to the control. To facilitate diagnostics, each device or component is assigned a Component Identifier (CID) which identifies the component. The VTh1S uses a four digit number to identify the specific component.

A typical VIMS installed on an off-highway truck may have up to 120 components (determined by configuration software) that provide information to the control. It is necessary to consult the appropriate service manual module and electrical schematic to determine the number of components and their CID's for each machine .

The third element of diagnostic information displayed on the message center is the Failure Mode Identifier (FMI). The FMI is a two digit number and describes the diagnosed fault within a particular component. Again, it will be necessary to consult the appropriate service manual or machine electrical schematic for specific machine FMI's.

Troubleshooting System Events

The following is an example of a system event occurring on a machine and the diagnostic information available to the operator or serviceman . During normal operation, the operator is alerted to a Category 2 warning. The alert indicator and the action lamp are both flashing. The message center displays the following information

INTERFACE CTL1 ERR

CALL SHOP

When the serviceman presses the FJ key on the keypad, the following information is displayed on line two

INTERFACE CTL1 ERR

MID57 CID0801 FMI12

NOTE: At this time, introduce and perform Lab Exercise B: Perform Message Center and Keypad Operations . This lab exercise will reinforce the material presented in the preceding slide presentation

VITAL INFORMATION MANAGEMENT SYSTEM

Reviewed by heri

on

4:06 AM

Rating:

Reviewed by heri

on

4:06 AM

Rating:

Reviewed by heri

on

4:06 AM

Rating:

Reviewed by heri

on

4:06 AM

Rating:

No comments: