POWER TRAIN

The transmission (2) is an Electronic Clutch Pressure Control (ECPC) countershaft transmission. The Transmission/Chassis ECM (not shown) controls the modulation of the clutch pressure in the transmission by suppling a variable output current to the appropriate proportional solenoid valve. The Transmission/Chassis ECM monitors the operator gear request, engine torque data from the Engine ECM, speed data from the transmission speed sensors, and the transmission temperature in order to determine the appropriate gear shift. The countershaft transmission has 8 forward speeds and 6 reverse speeds.The power flow through the machine is as follows:

- Engine (1)

- Countershaft transmission (2)

- Parking brake (3)

- Drive shaft (4)

- Differential and final drives (5)

- Chains (not shown)

- Sprocket (6)

- Wheel stations (7)

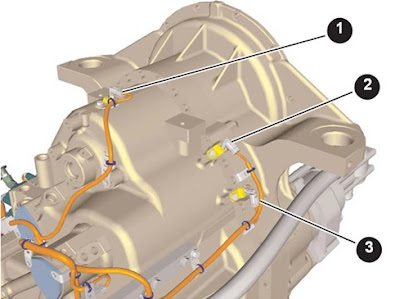

The Transmission/Chassis ECM (1) is the mounted on the transmission (2) at the rear of the machine. The power train electronic control system utilizes a variety of different types of devices that provide input data to the Transmission/Chassis ECM. The Transmission/Chassis ECM will use the input data to monitor the machine and also to determine if an output function is required. Most of the input circuits are monitored for diagnostics. The Transmission/Chassis ECM will log a diagnostic code if the ECM determines that an abnormal condition exists in one of the circuits.

The Transmission/Chassis ECM will also send output signals, which can have a variety of different functions. The types of electrical output signals are as follows:

- PWM proportional drivers

- On/Off sourcing drivers

- On/Off sinking drivers

- Sensor power supply

- Data link outputs

The Transmission/Chassis ECM also monitors the output circuits for diagnostics.

The Transmission/Chassis ECM has strategies that are used to protect the engine, power train, and machine components, reconfigure certain parameters, and test machine systems. The strategies are as follows:

Overspeed protection: This feature ensures that the transmission will never be shifted into a gear that would cause an engine overspeed condition. The Transmission/Chassis ECM monitors the transmission output speed sensors and the gear that is selected by the operator to determine if it is safe to shift the transmission.

Limp Home Mode: A limp home mode is available in order to provide an override to a transmission disabling diagnostic event. The limp home mode will be activated by the Transmission/Chassis ECM when a diagnostic code is activated for any of the transmission solenoids. The Transmission/Chassis ECM will allow the transmission to shift to gears that are not affected by the active diagnostic when the limp home mode is activated.

Low Voltage Shift Inhibit: This feature is designed to prevent excessive transmission clutch wear due to low system voltage by going to neutral whenever a shift is requested and the system voltage is low. When the system voltage drops below 20 volts, only shifts to neutral will be allowed any other shift will cause the transmission to shift to neutral. Once the transmission shifts to neutral due to low voltage, the transmission will remain in neutral until the system voltage is at or above 24 volts.

Maximum gear limit: This feature limits the maximum gear that the transmission will shift into both in forward and reverse. This feature is set using Electronic Technician and can be used to limit road speed. This feature is not the same as setting a minimum or maximum gear for autoshift.

Transmission/Chassis Electrical System.

Input Components:

Operator Present Switch: An input to the ECM that indicates if an operator is in the operator’s seat.Key Start Switch: Provides a signal to the Transmission/Chassis ECM when the operator wants to start the engine. The machine conditions must be met before the Transmission/Chassis ECM will energize the engine start relay.

Left Hand Joystick: Provides 10 different inputs to the Transmission/Chassis ECM. Some of those inputs include: directional control switch, upshift switch, and downshift switch.

Inching Pedal Position Sensor: An input to the ECM to modulate the current sent to the directional clutch in the transmission.

Iching nPedal Switch: An input to the ECM to indicate if the inching pedal has been depressed. The switch is used as a backup to the inching pedal position sensor

Transmission Input Speed Sensor: The sensor that measures the input speed of the transmission.

Transmission Intermediate Speed Sensors: The sensors measure the transmission intermediate speed. The ECM can determine direction of the transmission by looking at the difference in phase between the two sensors.

Transmission Output Speed Sensors: The sensors measure the transmission output speed. The ECM can determine direction of the transmission by looking at the difference in phase between the two sensors.

Transmission Oil Temperature Sensor: An input to the ECM that provides the temperature of the power train oil.

Transmission Filter Bypass Switch: An input to the ECM indicating when the transmission filter is in a bypass condition.

Parking Brake Switch: An input to the ECM that indicates the operator wants to release the parking brake.

Parking Brake Pressure Switch: An input to the ECM that provides the status of the pressure to the parking brake.

Service Brake Switches: Inputs to the ECM that indicates the operator has depressed the service brake pedal.

Service Brake Accumulator Pressure Sensor: An input to the ECM that provides the pressure in the service brake accumulators.

Right Steering Cylinder Position Sensor: Signals the ECM the position of the rod in the steering cylinder.

Left Steering Cylinder Position Sensor: Signals the ECM the position of the rod in the steering cylinder.

Articulation Angle Sensor 1 and 2: Signals the ECM the angle of the rear frame as compared to the angle of the front frame.

Differential Lock Switch: An input to the ECM that indicates the operator want to engage or disengage the differential lock.

Autoshift Switch: Signals the Transmission/Chassis ECM which shift mode the operator wants to operate on the machine. The operator can select between manual shifting or automatic shifting.

Fuel Level Sensor: An input to the ECM indicating the depth of the fuel in the fuel tank.

Air Conditioning Switch: An input to the ECM that indicates the operator want to activate the air conditioning.

Air Conditioning Pressure Switch: An input to the ECM that indicates if the air conditioning system has a low charge or a high charge condition. Based on the input from the switch, the ECM will protect the air conditioning compressor from damage.

+24 Battery Voltage: Unswitched power supplied to the Transmission/Chassis ECM from the battery.

Location Code 1: The location code pin number 1 is a grounded input signal that establishes the ECM is dedicated to power train and chassis operations. J1-26 pin on the Transmission/Chassis ECM connector is grounded.

Location Code Enable (GND): The location code enable is a grounded input signal to the Transmission/Chassis ECM that enables the location code enable feature. J1-32 pin on the Transmission/Chassis ECM connector is grounded.

Output Components:

Engine Start Relay: The Power Train ECM energizes the key start relay when the appropriate conditions are met to start the engine.

Secondary Steering Relay: The Transmission/Chassis ECM energizes the relay when the loss of steering pressure is detected by the ECM. The ECM energizes the relay and power is supplied to the secondary steering pump.

Differential Lock Relay: The Transmission/Chassis ECM energizes the differential lock relay when the operator depresses the differential lock switch.

Back-up Alarm Relay: The Transmission/Chassis ECM energizes the back-up alarm relay when the operator selects the REVERSE direction.

A/C Clutch Relay: The Transmission/Chassis ECM energizes the a/c clutch relay when air conditioning is requested.

Clutch Solenoids: The solenoids control the oil flow through the respective speed, range, and directional modulating valves.

Parking Brake Solenoid: The Transmission/Chassis ECM energizes the solenoid to release the parking brake when all the conditions have been met.

Secondary Steering Solenoids: The Transmission/Chassis ECM sends current to the solenoids in case of primary steering valve malfunction. The proportional solenoids control the oil flow to the spools in the primary steering control valve.

MSS Status LED: The Transmission/Chassis ECM illuminates the indicator LED with the status of MSS.

Autoshift Enabled LED: The Transmission/Chassis ECM illuminates the indicator LED when autoshift has be enabled.

+5 Volt Supply: Power supplied to the components from the Transmission/Chassis ECM.

+8 Volt Supply: Power supplied to the components from the Transmission/Chassis ECM.

+10 Volt Supply: Power supplied to the components from the Transmission/Chassis ECM

The secondary steering test switch (1) sends a signal to the Transmission/Chassis ECM that the operator wants to test the operation of the secondary steering system. When the switch (1) is depressed, the ECM energizes the secondary steering pump relay.

NOTE: The secondary steering test switch will activate the steering pump relay ONLY when the engine is running. Messenger must be used to test the secondary steering system when the engine is OFF.

The parking brake switch (2) sends a signal to the Transmission/Chassis ECM that the operator wants to release the parking brake. When an operator is present and the parking brake

switch (2) has been depressed, the ECM will energize the parking brake solenoid releasing the parking brake.

The key start switch (3) sends a signal to the Transmission/Chassis ECM that the operator wants to start the engine. The ECM determines if the directional control switch (not shown) is in the NEUTRAL position and if an operator is present. When the directional control switch is in the NEUTRAL position, the operator is present, and the key start switch (3) is turned to the START position, the ECM energizes the starter relay

Upshift switch (1) and downshift switch (2) allow the operator to manually upshift or downshift the gears in the transmission. When the operator commands a downshift that will overspeed the engine, the Transmission/Chassis ECM will not allow the downshift until it is safe to downshift

Directional control switch (3) signals the Transmission/Chassis ECM when the operator wants to shift into forward or reverse. The Transmission/Chassis ECM will not shift into forward or reverse if the ECM detects a signal from the transmission output speed sensors

The differential lock switch (1) is a momentary switch located on the front of right joystick (2). The differential lock defaults to the unlocked position when the machine is first started. Depressing the switch (1) sends a signal to the Transmission/Chassis ECM to energize the differential lock relay

Depressing the switch (1) again will send a signal to the ECM to de-energize the differential lock relay

The autoshift switch (1) has the following two modes of operation:

Manual Mode: When in the manual mode (shown), the operator to can manually change gears. Using the manual mode, the operator can send shift commands to the Transmission/Chassis ECM using the upshift and downshift buttons on the left joystick. This is the standard feature offered with the machine. The Autoshift feature can be purchased as an attachment.

Autoshift Mode: When in the automatic mode (top half of switch depressed), the Transmission/Chassis ECM automatically shifts the transmission through a range of gears that the operator sets. The operator can set the Minimum and Maximum gears that the autoshift function will shift between with messenger or Cat ET. The Transmission/Chassis ECM will determine when to shift within the operator selected gear range based on the transmission output speed. Any active diagnostics in the transmission will disable the autoshift function. Also, any active diagnostics for the FNR selector, autoshift switch, or parking brake system will disable the autoshift function. The autoshift feature will work in both the forward and reverse direction

The inching pedal (1) allows the operator to control the modulation of oil to the direction clutches. The inching pedal position sensor (2) sends a PWM signal to the Transmission/Chassis ECM to modulate the oil to the directional clutches. If the position sensor (2) has a failure, the inching pedal switch (3) is used for modulation of the directional clutches.

NOTE: Directional shifts can be made without the use of the inching pedal.

The service brake switch (4) sends a signal to the Transmission/Chassis ECM to disable the throttle lock.

The service brake light switch (5) is used to illuminate the brake lights at the rear of the machine.

The transmission is equipped with five speeds sensors that are monitored by the Transmission/Chassis ECM. The ECM uses these sensors to determine both the speed and direction of the transmission

The transmission input speed sensor (1) is located at the top of the transmission and provides the ECM with the transmission input shaft speed. The intermediate speed sensors (2) and (3) are located on the left middle side of the transmission and provides the ECM with the speed of an intermediate gear in the transmission. The transmission output speed sensors (4) and (5) are located on the lower right side of the transmission and provides the ECM with the transmission output speed

The Transmission/Chassis ECM uses these 5 speed sensors to continually monitor not only the speed of the transmission, but also the other speeds sensors to determine if they are working properly. The ECM can use the intermediate speed sensor to calculate transmission output speed in the event that the transmission output speed sensors fail. The ECM can also use the transmission input speed sensor to calculate the transmission output speed in the event that both the transmission output speed sensors and intermediate speed sensors fail.

The transmission relief valve is located on the left side of the transmission and sets the working pressure of the transmission hydraulic system The transmission relief valve has a pressure

tap (1) that tests the relief pressure of the transmission hydraulic system. The transmission relief valve is adjustable.

The transmission has a temperature sensor (2) which is used by the Transmission/Chassis ECM to monitor the transmission oil temperature.

The engine start relay (1) is controlled by the Transmission/Chassis ECM. When the signal is sent to the ECM to start the engine, the ECM then sends current to the start relay. The coil in the relay closes and battery voltage is sent to the starter motor.

Also shown is the main power relay (2).

The secondary steering relay (1) is located in the rear frame near the articulation hitch. The secondary steering relay is energized in the case of a malfunction of the primary implement/steering pump.

Also shown is the secondary steering pump (2).

The differential lock relay (arrow) is energized by the Transmission/Chassis ECM when the differential lock switch is depressed.

The back-up alarm relay (1) is energized by the Transmission/Chassis ECM when the directional control switch in placed in the REVERSE position. The A/C clutch relay (2) is energized by the Transmission/Chassis ECM when air conditioning is requested.

Also shown is the back-up alarm (3).

Power Train Hydraulic System

Oil from the transmission sump passes through a magnetic screen and is pumped by the scavenge section of the transmission pump to the differential sump. Oil from the differential sump is pumped by the charging section of the transmission pump to the power train filter.Filtered oil travels to the following locations in the power train hydraulic system:

* Park brake solenoid: The park brake solenoid has two positions. When the solenoid is de-energized, supply oil will be directed to flow through the parking brake and lubricate the internal components of the park brake before draining back into the transmission case. When the solenoid is energized, supply oil is directed to compress an internal spring inside the park brake housing which releases the parking brake.

* Differential lock solenoid: When the differential lock solenoid is de-energized, the differential lock is open to drain. Oil is allowed to drain from the clutch pack and the differential unlocks. When the differential lock solenoid is energized, supply oil is directed to the differential to engage the differential lock. The differential oil compresses a clutch pack which locks the differential side gear to the case.

* Eight modulating valves: The clutch modulation valves control the engagement of the transmission clutches. The solenoids are controlled by a Pulse Width Modulated (PWM) signal from the Transmission/Chassis ECM. Supply oil flows into the clutch modulation valves and through a passage in the center of the spool. Oil then flows to the tank if the solenoid is not energized. Oil flow is blocked by a ball and seat if the solenoid is energized. The spool will shift and the clutch will begin to fill. The signal from the Transmission/Chassis ECM determines how long it takes to fill each clutch. Modulating valve number (7) has a relief valve on the return line to the tank. The relief valve maintains 14 kPa (2 psi) of back pressure on the tank return line in order to keep the number (7) clutch full of oil.

* Transmission temperature sensor: The transmission oil temperature sensor is used by the Transmission/Chassis ECM to monitor the transmission temperature.

* Main relief valve: The main relief valve regulates the supply pressure inside the transmission hydraulic system. Oil unseats the check ball and forces the spool to the right if the transmission system pressure becomes greater then the spring force on the right of the spool. Excess oil will flow to the power train cooler or to lubricate the flywheel.

Excess oil from the main relief valve flows to the power train cooler. The cooler is protected from excessive pressure by a relief valve. From the cooler, oil flows to internal components of the transmission for lubrication. The lubrication circuit is also protected by a relief valve.

The transmission pump is a two-section pump. The scavenge section (1) pumps oil from the transmission sump to the differential sump. The charging section (2) pumps oil from the differential sump to the power train hydraulic system.

The power train filter (1) is located on the right rear of the transmission case. The power train filter (1) is equipped with a filter bypass switch. The tap (2) is an S•O•S port. The tap (3) is a pressure tap for testing pump supply pressure.

The clutch modulating valves are mounted on the rear of the transmission on the left side of the transmission. There is one modulating valve for each of the eight transmission clutches. The pressure taps in the modulating valves test the clutch pressures for the following:

* Clutch 1 (1) (forward high)

* Clutch 2 (2) (forward low)

* Clutch 3 (3) (reverse)

* Clutch 4 (4) (second speed)

* Clutch 5 (5) (third speed)

* Clutch 6 (6) (first speed)

* Clutch 7 (7) (low range)

* Clutch 8 (8) (high range)

The transmission cooler relief valve (1) is located under the main relief. The cooler relief valve protects the power train oil cooler from excessive pressure.

The transmission lubrication relief valve (2) is located to the right of the main relief valve. The lubrication relief valve protects the lubrication system of the transmission from excessive pressure.

The relief valve (3) for the low range solenoid valve is located under the solenoid valve. The relief valve is used for improved modulation of the low range clutch.

The power train cooler (1) is located on the right rear side of the engine. The power train cooler uses engine coolant to remove the heat from the power train oil before it returns back to the transmission for lubrication.

The differential lock solenoid (arrow) is located on the left rear side of the differential case. The differential lock solenoid is turned off and on by the differential lock relay. The relay is turned off and on by the differential lock switch located in the right operator joystick.

The differential (1) is equipped with a hydraulically engaged differential lock (4) which improves traction in poor underfoot conditions. The differential lock uses a clutch pack (5) to lock one differential side gear to the spider gear case.

The final drives (2) are also located in the same case as the differential. The final drives use gears to multiply the torque before it reaches the wheels.

The differential and final drive (3) is a modular design that improves serviceability. This new design also improves on contamination control since the differential and final drive no longer needs to be serviced in the machine.

This illustration shows the power flow through the countershaft transmission. The countershaft transmission provides eight forward speeds and six reverse speeds. The transmission contains eight clutches which are engaged hydraulically and released by spring force. The input shaft is driven by the flywheel of the engine.

Also shown is the parking brake.

This illustration shows the transmission hydraulic system with the engine running and the directional control switch in the NEUTRAL position.

When the engine is running, flow from the transmission scavenge pump is sent from the transmission sump to the differential housing. Oil flow from the transmission charge pump is sent from the differential housing through the transmission filter to the eight transmission modulating valves. Transmission charge pump flow is also sent to the transmission relief valve, parking brake solenoid valve, and the differential lock solenoid valve. The transmission relief valve limits the oil pressure to the modulating valves. When NEUTRAL is selected, the Transmission/Chassis ECM energizes No. 5 and No. 8 solenoids. The modulating valve controls the oil flow to the clutches.

When the solenoids are energized, the electromagnetic force moves the pin against the ball. The ball moves to the right against the seat. The oil flow through the center of the valve spool is blocked. The oil pressure increases at the left end of the spool and the valve spool moves to the right compressing the spring. Oil flow is then directed to the clutches

From the transmission relief valve, oil flows to the power train oil cooler and the power train oil cooler relief valve. The relief valve limits the oil pressure to the cooler. When the oil pressure to the cooler exceeds 520 kPa (75 psi), the relief valve opens and sends the excess oil pressure to the outlet side of the oil cooler.

Oil flows through the power train oil cooler and on to the transmission for cooling and lubrication purposes. The lubrication system of the transmission has a relief valve to limit the oil pressure. When the oil pressure in the lubrication system exceeds 380 kPa (55 psi), the relief valve opens and sends the excess oil pressure to the transmission sump.

This illustration shows the transmission hydraulic system with the engine running, the directional control switch in the FORWARD position, and FIRST SPEED selected.

When FIRST SPEED FORWARD is selected, the Transmission/Chassis ECM energizes the No. 6, and No. 7 solenoids before energizing the No. 1 solenoid. The modulating valves control the oil flow to the clutches.

TRANSMISSION MODULATING VALVE.

NO COMMANDED SIGNAL

Transmission Modulating Valve - No Commanded SignalIn this illustration, the transmission modulating valve is shown with no current signal applied to the solenoid. The Transmission/Chassis ECM controls the rate of oil flow through the transmission modulating valves to the clutches by changing the signal current strength to the solenoid. With no current signal applied to the solenoid, the transmission modulating valve is DE-ENERGIZED and oil flow to the clutch is blocked. The transmission modulating valve is located on the transmission control valve.

Pump oil flows into the valve body around the valve spool and into a drilled passage in the center of the valve spool. The oil flows through the drilled passage and orifice to the left side of the valve spool to a drain orifice. Since there is no force acting on the pin assembly to hold the ball against the drain orifice, the oil flows through the spool and the drain orifice past the ball to the tank.

The spring located on the right side of the spool in this view holds the valve spool to the left. The valve spool opens the passage between the clutch passage and the tank passage and blocks the passage between the clutch passage and the pump supply port. Oil flow to the clutch is blocked. Oil from the clutch drains to the tank preventing clutch engagement.

TRANSMISSION MODULATING VALVE

COMMANDED SIGNAL BELOW MAXIMUM

Transmission Modulating Valve - Commanded Signal Below Maximum.

In this illustration, the modulating valve is shown with a signal to the solenoid that is below the maximum current. Clutch engagement begins when the Transmission/Chassis ECM sends an initial current signal to ENERGIZE the solenoid. The amount of commanded current signal is proportional to the desired pressure that is applied to the clutch during each stage of the engagement and disengagement cycle.The start of clutch engagement begins when the current signal to the solenoid creates a magnetic field around the pin. The magnetic force moves the pin against the ball in proportion to the strength of the current signal from the ECM.

The position of the ball against the orifice begins to block the drain passage of the oil flow from the left side of the valve spool to the tank. This partial restriction causes the pressure at the left end of the valve spool to increase. The oil pressure moves the valve spool to the right against the spring. As the pressure on the right side of the valve spool overrides the force of the spring, the valve spool shifts to the right.

The valve spool movement starts to open a passage on the right end of the valve spool for pump supply oil to fill the clutch. Oil also begins to fill the spring chamber on on the right end of the spool.

In the initial clutch filling stage, the ECM commands a high current pulse to quickly move the valve spool to start filling the clutch. During this short period of time, the clutch piston moves to remove the clearances between the clutch discs and plates to minimize the amount of time required to fill the clutch. The ECM then reduces the current signal which reduces the pressure setting of the proportional solenoid valve. The change in current signal reduces the flow of oil to the clutch. The point where the clutch plates and discs start to touch is called TOUCH-UP.

Once TOUCH-UP is obtained, the ECM begins a controlled increase of the current signal to start the MODULATION cycle. The increase in the current signal causes the ball and pin to further restrict oil through the drain orifice to tank causing a controlled movement of the spool to the right. The spool movement allows the pressure in the clutch to increase.

During the MODULATION cycle, the valve spool working with the variable commanded current signal from the ECM acts as a variable pressure reducing valve.

The sequence of partial engagement is called desired slippage. The desired slippage is controlled by the application program stored in the ECM.

TRANSMISSION MODULATING VALVE

COMMANDED SIGNAL AT MAXIMUM.

Transmission Modulating Valve - Commanded Signal At Maximum.

In this illustration, the modulating valve is shown with a maximum current signal commanded to the solenoid. When the modulation cycle stops, the Transmission/Chassis ECM sends the maximum specified current signal to fully engage the clutch.The constant current signal pushes the pin firmly against the ball in the solenoid valve. The pin force against the ball blocks more oil from flowing through the drain orifice. This restriction causes an increase in pressure on the left side of the valve spool. The valve spool moves to the right to allow pump flow to fully engage the clutch.

In a short period of time, maximum pressure is felt at both ends of the proportional solenoid valve spool. This pressure along with the spring force on the right end of the spool causes the valve spool to move to the left until the forces on the right end and the left end of the valve spool are balanced.

The valve spool movement to the left (balanced) position reduces the flow of oil to the engaged clutch. The ECM sends a constant maximum specified current signal to the solenoid to maintain the desired clutch pressure.

The different maximum specified pressures for each clutch is caused by different maximum current signals being sent by the ECM to each individual modulating valve. The different maximum signal causes a difference in the force pushing the pin against the ball to block leakage through the drain orifice in each solenoid valve. The different rate of leakage through the spool drain orifice provides different balance positions for the proportional solenoid valve spool. Changing the valve spool position changes the flow of oil to the clutch and the resulting maximum clutch pressure.

The operation of the proportional solenoid to control the engaging and releasing of clutches is not a simple on and off cycle. The ECM varies the strength of the current signal through a programmed cycle to control movement of the valve spool

This illustration shows the transmission hydraulic system with the engine running, the directional control switch in the FORWARD position, and SECOND SPEED selected

When SECOND SPEED FORWARD is selected, the Transmission/Chassis ECM energizes the No. 4, and No. 7 solenoids before energizing the No. 2 solenoid. The modulating valves control the oil flow to the clutches.

This illustration shows the transmission hydraulic system with the engine running, the directional control switch in the REVERSE position, and FIRST SPEED selected

When FIRST SPEED REVERSE is selected, the Transmission/Chassis ECM energizes the No. 6, and No. 7 solenoids before energizing the No. 1 solenoid. The modulating valves control the oil flow to the clutches. The speed and range clutches are engaged first when three new clutches are used during a gear change..

THANK YOU HAVE VISITED ON WWW.GOSGT.COM

POWER TRAIN ON 16M GRADER CATERPILLAR

Reviewed by heri

on

4:54 PM

Rating:

Reviewed by heri

on

4:54 PM

Rating:

Reviewed by heri

on

4:54 PM

Rating:

Reviewed by heri

on

4:54 PM

Rating:

No comments: