TORQUE CONVERTER 797 TRUCK.

POWER TRAIN

Torque ConverterThe first component in the power train is the torque converter. The torque converter provides a fluid coupling that permits the engine to continue running with the truck stopped. In converter drive, the torque converter multiplies engine torque to the transmission. At higher ground speeds, a lockup clutch engages to provide direct drive. The NEUTRAL and REVERSE ranges are converter drive only. FIRST SPEED is converter drive at low ground speed and direct drive at high ground speed.

SECOND through SEVENTH SPEEDS are direct drive only. The torque converter goes to converter drive between each shift (during clutch engagement) to provide smooth shifts.

Some of the major power train components mounted on the torque converter housing are:

1. Inlet relief valve

2. Outlet relief valve

3. Torque converter lockup valve

4. Power train pump (transmission scavenge and control)

5. Power train pump (transmission lube and T C charging)

6. Torque converter charging filter

7. Torque converter outlet screen (behind cover at top)

8. Torque converter magnetic suction screen (behind cover at bottom).

Torque converter rear housing.

Shown is the inside of the rear torque converter housing. Items shown are:

1. Power train pump drive gears

2. Magnetic suction screen oil passage

3. Torque converter inlet oil passage

4. Torque converter outlet screen oil passage

5. Torque converter lockup oil passage.

797B torque converter.

The 797B torque converter is shown in the front housing. Torque converter inlet (charging) oil enters the torque converter through passage (1) and exits through a passage on the other side of the torque converter.

Torque converter lockup oil enters the torque converter through passage (2).

Shown below the two oil passages is the gear that is used to turn the power train pump drive gears.

Torque converter magnetic screen cover.

Oil is pulled from the torque converter housing through a magnetic screen located in the lower bore behind the cover (1). The transmission control, the torque converter charging, and the transmission lube pumps pull oil from the torque converter case through the magnetic screen and the three suction tubes (2) at the bottom of the torque converter case.

Oil that is scavenged from the transmission case through the magnetic screen located at the bottom of the transmission case returns to the torque converter through a diffuser located behind the cover (3). Located in the upper bore behind the cover (1) is the torque converter outlet screen. The torque converter outlet screen bypass switch (4) is

located on the cover. The torque converter outlet screen bypass switch provides an input signal to the Transmission ECM. The Transmission ECM sends the signal to the VIMS, which informs the operator if the torque converter outlet screen is restricted.

Also located on the cover is the torque converter oil temperature sensor (5). The torque converter oil temperature sensor provides an input signal to the Transmission ECM. The Transmission ECM sends the signal to the VIMS, which informs the operator of the torque converter oil temperature.

Right side power train pump.

The power train pump on the right side of the torque converter case has

two sections:

* Rear section--Transmission lubrication

* Front section--Torque converter charging

Oil flows from the rear pump section through port (1) to the transmission lube valve located on the left rear side of the transmission case.

Oil flows from the front pump section through the torque converter charging filter (2) to the torque converter inlet relief valve. Transmission control oil from the transmission control flows through port (3) and joins with the oil from the torque converter charging pump.

Located on top of the torque converter charging filter are two pressure taps. The left pressure tap (4) can be used to measure the unfiltered torque converter charging pressure. The right pressure tap (5) can be used to measure the filtered torque converter charging pressure. Together, these two taps can be used to calculate the oil filter restriction. Torque Converter oil samples can be taken at the Scheduled Oil Sampling (S•O•S) tap (6) located in the top center of the filter housing.

An oil filter bypass valve (7) is located on the torque converter charging filter. The bypass valve will open to provide flow to the torque converter charging system if the filter is restricted.

An oil filter bypass switch (8) is also located on the filter housing. The bypass switch provides an input signal to the Transmission ECM. The Transmission ECM sends the signal to the VIMS, which informs the operator if the filter is restricted.

Torque converter inlet relief valve.

Inlet relief pressure should be: 170 ± 70 kPa (25 ± 10 psi) at LOW IDLE and 896 ± 70 kPa (130 ± 10 psi) at HIGH IDLE. Normally the inlet relief pressure will be greater than the outlet relief valve pressure. The pressure tap (3) (labeled P2 on valve) above the inlet relief relief tap will show drain oil pressure. This tap will not normally be used.

Oil flows through the inlet relief valve and enters the torque converter.

Some of the oil will leak through the torque converter and fall to the bottom of the housing. Most of the oil in the torque converter is used to provide a fluid coupling and flows through the torque converter outlet relief valve (4). The outlet relief valve maintains the minimum pressure inside the torque converter. The main function of the outlet relief valve is to keep the torque converter full of oil to prevent cavitation. An orifice is installed in parallel with the outlet relief valve.

The outlet relief pressure can be measured at the tap (5) on the outlet relief valve. Outlet relief pressure will vary significantly with oil temperature. With 30 weight TDTO oil at 80°C (175°F), outlet relief pressure should be: 140 ± 70 kPa (20 ± 10 psi) at LOW IDLE and 620 ± 70 kPa (90 ± 10 psi) at HIGH IDLE.

The pressure tap (6) to the left of the outlet relief tap will show oil pressure on the cooler side of the outlet orifice. This tap will not normally be used.

The inlet and outlet relief valves can be adjusted with a screw located behind the covers (7) at the ends of the valves.

Generally, torque converter stall speed (in gear, full throttle, 0 ground speed) is used to determine if there is an engine power or a torque converter problem. For example, if engine power is known to be within specification and the stall speed is high, the

torque converter may have a problem (low internal oil pressure, poor internal tolerances or damaged components).

The 797B cannot use torque converter stall to indicate a torque converter problem. The 797B uses a torque limiting strategy. When the 797B is operated at torque converter stall, the Engine ECMs limit engine speed to 1600 ± 65 rpm. On other trucks, if the torque converter is slipping the rpm will increase. But on the 797B, the Engine ECMs will hold the engine speed at 1600 rpm.

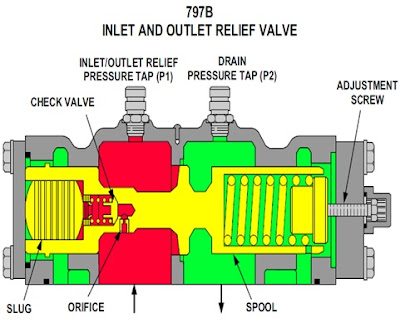

Torque converter inlet and outlet relief valves.

Shown is a sectional view of the torque converter inlet and outlet relief valves. The valves are the same, but the pressure settings are different.

Supply oil to the relief valves flows through an orifice in the spool, past a check valve, and enters the slug chamber. The check valve dampens spool movement and reduces the possibility of valve chattering and pressure fluttering. Oil pressure moves the slug in the left end of the spool to the left and the spool moves to the right against the spring force.

The slug reduces the effective area on which the oil pressure can push.

Because of the reduced effective area, a smaller, more sensitive spring can be used. Relief pressure will be equal to the force of the spring on the right end of the spool. The spring force can be adjusted with the adjustment screw.

Torque converter outlet relief valve.

Oil returns from the power train oil coolers to the torque converter housing through a tube located at the right front side of the torque converter housing.

Torque converter lockup valve.

The torque converter lockup valve is mounted at the top of the torque converter housing. The lockup valve uses transmission control oil from the transmission control filter to provide torque converter lockup. The Transmission ECM energizes the lockup solenoid (1) to engage the lockup clutch in the torque converter. The Transmission ECM must receive at least one of the two Transmission Output Speed (TOS) signals and the Converter Output Speed (COS) signal before it will energize the lockup solenoid. The lockup solenoid is energized when ground speed is approximately 6.4 km/h (4 mph).

Torque converter lockup clutch pressure can be measured at the tap (2) on the lockup valve. Lockup clutch pressure should be:

* Converter Drive--0 to 35 kPa (0 to 5 psi)

* Direct Drive--2067 ± 140 kPa (300 ± 20 psi)

Since engine speed will always be approximately 1300 rpm or greater when the torque converter is in DIRECT DRIVE, check the torque converter lockup pressure at 1300 rpm.

If the lockup clutch pressure is not correct, check for loose or sticking

components or debris in the valve. If the lockup valve is operating

correctly and the lockup pressure is incorrect, verify that the correct

"flash" file is installed in the Transmission ECM. Lockup clutch pressure

can be adjusted in the Calibration mode of ET.

The Converter Output Speed (COS) sensor (3) sends an input signal to the

Transmission ECM. The Transmission ECM memory also contains the

Engine Output Speed (EOS) and the Transmission Output Speed (TOS).

The Transmission ECM provides all of these input signals to the VIMS.

Using the information from the Transmission ECM, the VIMS calculates if any slippage exists in the torque converter lockup clutch or any of the transmission clutches and stores this information in the VIMS main module. This information can be downloaded from the VIMS with a laptop computer.

Lockup clutch control valve operation.

When the control spool moves to the right, pump supply oil flows to the lockup clutch. The Transmission ECM opens and closes the ball drain port as needed to maintain the correct lockup clutch pressure.

The lockup clutch valve is often referred to as the Electronic Clutch Pressure Control (ECPC) valve because it can control clutch pressure electronically. The same type valve is used to engage the transmission clutches.

Lockup clutch control valve operation

When the control spool moves to the right, pump supply oil flows to the lockup clutch. The Transmission ECM opens and closes the ball drain port as needed to maintain the correct lockup clutch pressure. The lockup clutch valve is often referred to as the Electronic Clutch Pressure Control (ECPC) valve because it can control clutch pressure

electronically. The same type valve is used to engage the transmission clutches.

THANK YOU FOR YOUR VISITING IN WWW.GOSGT.COM

TORQUE CONVERTER 797 TRUCK

Reviewed by heri

on

8:29 PM

Rating:

Reviewed by heri

on

8:29 PM

Rating:

Reviewed by heri

on

8:29 PM

Rating:

Reviewed by heri

on

8:29 PM

Rating:

No comments: