INTRODUCTION

This course will cover organization of the failure analysis process, distinction between causes and results, stress dealing in facts, thinking logically with those facts, and communicating findings to others.INSTRUCTOR NOTE: The instructor should welcome members of the class, make proper introductions, establish his own credentials to teach this class, and go through "housekeeping" rules such as break times, lunch arrangements, rest room locations, smoking restrictions, formal or informal discussion format, etc.

Exciting

Failure analysis is exciting and enjoyable when the failure analyst can discover what caused an unexpected problem and recommend the right corrective action.

Customer reaction

Failure analysis is also exciting, but not so enjoyable, when the analyst cannot find the cause of a problem and must face an unhappy customer.Customers become dissatisfied when service technicians fix symptoms or results instead of root causes of failures.

Customers are also unhappy when they are invoiced for an early hour repair and do not understand why the failure was their responsibility.

COURSE PURPOSE

The purpose of this failure analysis course is to help strengthen students' failure analysis ability and improve their effectiveness with customers.

COURSE OVERVIEW

This course will cover:* Introduction to failure analysis

* Failure analysis management

* Metallurgy

* Principles of fractures

* Principles of wear

* Visual examination

* Application of basic principles to components.

NOTE: The instructor should at this time review any course handouts that the students have been given.

Basic principles

This course concentrates on basics -- basic ideas about management, metallurgy, wear and fractures that can be applied to all products and customers in all parts of the world.

Before analysis

The course will stress thinking in an orderly fashion before beginning analysis work.

During analysis

The course will also stress working in an orderly fashion during an analysis to help the analyst continue to think orderly.

Introduction title slide

This slide will be shown many times throughout the course. By the conclusion of the course, students will understand and be able to explain the meaning of the investigating team, the footprints and the road signs.

Applications

Caterpillar products are found in an increasing variety of applications.

World map

Caterpillar products are used in all the nations of the world.

Competition

Competition is also present and is very aggressive.

Value

Customers constantly compare Caterpillar value to the value of competitive products.Caterpillar and Caterpillar dealers must therefore continue to find ways to offer customers superior value to outperform competition.

Value = sales

When customers perceive that Caterpillar products give best value, then Caterpillar and Caterpillar dealers achieve the goal of increasing sales of products, parts, and services.To keep customers buying Caterpillar products, Caterpillar products must perform to user expectations.

Customer expectations

Customers expect Caterpillar products to run reliably and efficiently.When problems occur, customers want them quickly and professionally solved.

RESPONSIBILITIES

Three primary parties are involved in successful product performance: the factory, the dealer, and the customer. Each party has specific responsibilities that must be met if the product is to perform well.

Factory responsibilities

The factory has design, materials, and workmanship responsibilities.The factory also shares responsibility with dealers in identifying and correcting product problems.

Quality products

Factory emphasis and expertise is concentrated on producing quality products.

Customer responsibilities

The customer is responsible for maintenance, operation, application and assisting in problem identification.The factory and dealers can publish excellent guidelines for maintenance, application and operation, but to get full value the customer must put the guidelines into practice.

Customer responsibilities

Frequently customers do not have the guidelines or, if they have them, do not understand the things they must do.Many problems will be avoided if each customer obtains and understands maintenance and operation guidelines. This understanding will allow the customer to identify early warning signs of problems, bring problems to the dealer's attention, and take corrective action before failure.

Dealer responsibilities

The dealer has sales and service responsibilities. Sales responsibilities include insuring that each customer has appropriate guidelines and that the customer understands product application, installation and maintenance requirements.Service responsibilities include quick problem analysis leadership and efficient problem identification and correction.

Familiarity with customer operations

Quick problem identification usually requires prior familiarity with customer products, facilities, operations and maintenance practices.

Time with customer

Time spent with each customer also helps the dealer discover customer misunderstandings about proper operation or maintenance that can lead to product problems.

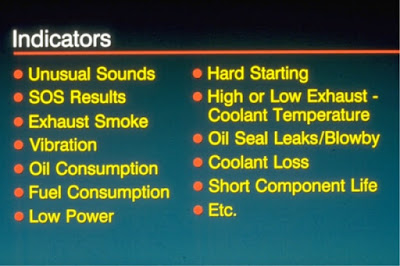

INDICATORS

There are often physical indicators of health problems.Physical Indicators of product, operational or maintenance problems

Products also have physical indicators of product, operational or maintenance problems.

Patient expectations

Patients expect a doctor to identify problems by observing indicators.

Customer expectations

Customers expect the dealer to observe product indicators and identify exactly what is wrong.

Quality interview

Patients appreciate a quality interview with the doctor after the doctor's inspections.

Quality interview

Similarly, customers appreciate a quality interview to discuss results of inspections of products, maintenance and operations.As dealer service technicians gain experience in failure analysis and become able to read early warning signs more accurately, they become able to recognize problems in beginning stages and prevent failures.

Goals

One of the dealer service technician's goals is to become good enough at observing product and environmental indicators to spot problems early and make repairs before failure.However, there will be times when unexpected failures do occur and dealer service personnel will need to perform high quality failure analysis to satisfy customers.

Challenge

When failures occur, the analyst's challenge is to determine the exact cause and best corrective action.

KEY TERMS

Failure analysis is defined as "thoughtful review of product and environmental facts which leads to identification of root causes of product problems.

Failure analysis fact sources

Failure analysis facts can be obtained from three basic sources:1. The customer jobsite

2. The failed product

3. Metallurgical labs

Most problems can be solved by taking full advantage of sources 1 and 2. Occasionally, microstructure facts from source 3 are needed to identify

root causes..

Root cause

Root cause is defined as "the specific condition that began the problem."The term "root cause" is a focal point of this course, which covers techniques to identify root cause damage versus resultant damage.

Failure analysis team

This course will also discuss the roles of the failure analysis team members involved in identifying root causes and taking corrective action."Team" members include customer operations and maintenance people, dealer line and support people, and factory line and support people.

All of these team members play important roles, but best results are obtained when the dealer with the problem assumes overall problem solution responsibility and manages the failure analysis investigation.

Communication leads

The root cause of a problem must be effectively communicated to all team members, and especially to the party responsible for the failure. Each team member needs to understand the problem cause and results, and good communication helps establish this understanding.

Eight steps of applied failure analysis

Applied failure analysis can be organized as eight steps to help the analyst perform a quality problem analysis.Not doing a step, or doing steps out of order, can result in wrong root cause identification, wrong corrective action (fixing problem results rather than causes), unnecessarily high invoices and downtime, and dissatisfied customers.

These eight steps are:

1. State the problem clearly and concisely.

2. Organize fact gathering.

3. Observe and record facts.

4. Think logically with the facts.

5. Identify the most probable root cause.

6. Communicate with the party responsible for the failure.

7. Make repairs as directed by the responsible party.

8. Follow up with the customer.

CONCLUSION

Professional failure analysis is hard work and requires the commitment and careful effort of all team members.Dealer managers need to be fully committed to finding the root causes of failures and should insure that service personnel are trained and have the time to do good failure analysis.

Service

With each new problem the analyst may ask "how can we best use this opportunity to serve the customer and establish his trust in us?"

Satisfy customers

By carefully planning product support for each customer, finding the root cause for each failure, and building a good perception of value in each customer's mind, the dealer will satisfy customers and increase sales of products, parts, and service.

Lecture end

This concludes the introduction to applied failure analysis.

INTRODUCTION FAILURE ANALYSIS

Reviewed by heri

on

4:15 AM

Rating:

Reviewed by heri

on

4:15 AM

Rating:

Reviewed by heri

on

4:15 AM

Rating:

Reviewed by heri

on

4:15 AM

Rating:

No comments: