POWER TRAIN

Power flows from the engine to the rear wheels through the power train.

The components of the power train are:

* Torque converter

* Transfer gears

* Transmission

* Differential

* Final drives

Torque Converter

The first component in the power train is the torque converter. The torque converter provides a fluid coupling that permits the engine to continue running with the truck stopped. In converter drive, the torque converter multiplies engine torque to the transmission. At higher ground speeds, a lockup clutch engages to provide direct drive.

The NEUTRAL and REVERSE ranges are converter drive only. FIRST SPEED is converter drive at low ground speed and direct drive at high ground speed.

SECOND through SEVENTH SPEEDS are direct drive only. The torque

converter goes to converter drive between each shift (during clutch

engagement) to provide smooth shifts.

Mounted on the torque converter are the inlet relief valve (1), the outlet

relief valve (2) and the torque converter lockup clutch control valve (3).

A torque converter outlet temperature sensor (4) provides an input signal to the Transmission/Chassis ECM. The Transmission/Chassis ECM sends the signal to the Caterpillar Monitoring System, which informs the operator of the torque converter outlet temperature.

The torque converter pump (5) consists of three or four sections. The pump sections from front to rear are:

* torque converter scavenge

* torque converter charging

* parking brake release

* brake cooling (oil cooled front brakes only)

CONVERTER DRIVE

This sectional view shows a torque converter in CONVERTER DRIVE.

The lockup clutch (yellow piston and blue discs) is not engaged. During operation, the rotating housing and impeller (red) can rotate faster than the turbine (blue). The stator (green) remains stationary and multiplies the torque transfer between the impeller and the turbine. The output shaft rotates slower than the engine crankshaft, but with increased torque.

DIRECT DRIVE

Torque Converter Hydraulic System

The three (caliper disc front brakes) or four (oil cooled front brakes) section torque converter pump is located at the bottom rear of the torque converter. The four sections (from the front to the rear) are:

* Torque converter scavenge (1)

* Torque converter charging (2)

* Parking brake release (3)

* Brake oil cooling (4) (oil cooled front brakes only)

Excess oil that accumulates in the bottom of the torque converter is scavenged by the first section of the pump through a screen behind the access cover (5) and returned to the hydraulic tank.

Torque converter charging filter

Oil flows from the torque converter charging section of the pump to the torque converter charging filter (1). The filter is located on the frame behind the left front tire.

Hoist, converter and brake oil samples can be taken at the Scheduled Oil Sampling (S.O.S) tap (2).

Torque converter inlet relief valve

Oil flows from the torque converter charging filter to the torque converter inlet relief valve (1). The inlet relief valve limits the maximum pressure of the supply oil to the torque converter. The torque converter inlet relief pressure can be measured at this valve by removing a plug (2) and installing a pressure tap. Inlet relief pressure should not exceed 930 ± 35 kPa (135 ± 5 psi) at high idle when the oil is cold. Normally, the

inlet relief pressure will be slightly higher than the outlet relief valve

pressure.

Oil flows through the inlet relief valve and enters the torque converter.

Some of the oil will leak through the torque converter to the bottom of the housing to be scavenged. Most of the oil in the torque converter is used to provide a fluid coupling and flows through the torque converter outlet relief valve (3). The outlet relief valve maintains the minimum pressure inside the torque converter. The main function of the outlet relief valve is to keep the torque converter full of oil to prevent cavitation. The outlet relief pressure can be measured at the tap (4) on the outlet relief valve.

The outlet relief pressure should be 380 to 515 kPa (55 to 75 psi) at 1540 to 1670 rpm (TC Stall).

A torque converter outlet temperature sensor (5) provides an input signal to the Caterpillar Monitoring System, which informs the operator of the torque converter outlet temperature.

Hoist, converter and brake oil cooler

Most of the oil from the torque converter outlet relief valve flows through a screen (1) and the hoist, converter and brake oil cooler (2) located on the right side of the engine.

The torque converter charging oil flows through the hoist, converter and brake oil cooler and the rear brakes before returning to the hydraulic tank.

Parking brake release filter (arrow)

Oil flows from the parking brake release section of the torque converter pump to the parking brake release filter (arrow).

Parking brake release valve

Oil from the parking brake release filter flows to the parking brake release valve (1). The valve is located inside the left frame near the torque converter. The parking brake release section of the torque converter pump provides supply oil for several purposes:

* Release the parking brakes

* Engage the torque converter lockup clutch

* Hoist valve pilot oil

* Brake oil cooling

The parking brake relief valve (2) controls the pressure for parking brake release, torque converter lockup and hoist valve pilot oil. The parking brake release pressure is 4700 ± 200 kPa (680 ± 30 psi).

Most of the oil from the parking brake release valve flows through the brake oil cooler and is used to cool the brakes.

Torque converter lockup clutch valve supply port

Torque converter lockup clutch pressure can be tested at the tap (3). With engine speed at1300 rpm, torque converter lockup clutch pressure should be 2135 ± 70 kPa (310 ± 10 psi).

To check the lockup clutch pressure, the transmission must be in NEUTRAL. Disconnect the connectors from the upshift and downshift solenoids. The downshift solenoid is always energized in NEUTRAL.

Therefore, +24 Volts will be available at the downshift solenoid harness connector to energize the lockup solenoid. With the engine rpm at LOW IDLE, use two jumper wires to connect the downshift solenoid harness to the lockup solenoid. The lockup clutch will engage.

The lockup clutch maximum pressure is not adjustable. If the lockup clutch maximum pressure is not correct, verify that the lockup clutch primary pressure is correct. If the lockup clutch primary pressure is correct, check for loose or sticking components or debris in the valve. If these components are not the problem, change the load piston springs. If the load piston springs are replaced, be sure to reset the lockup clutch

primary pressure.

Lockup clutch valve in TC drive

Shown is a sectional view of the torque converter lockup clutch valve in TORQUE CONVERTER DRIVE or NEUTRAL. Supply oil from the parking brake release pump is used to provide lockup clutch oil and has two functions:

1. Supply pressure is reduced to provide pilot pressure to the solenoid valve.

2. When the solenoid is energized, supply pressure is reduced by the modulation reduction valve to provide lockup clutch pressure.

First, supply pressure is reduced to provide pilot pressure to the lockup solenoid. Supply oil to the pressure reduction valve flows through crossdrilled orifices in the spool, past a check valve and enters the slug chamber. The check valve dampens spool movement and reduces the possibility of valve chatter and pressure fluctuation. Oil pressure moves

the slug in the right end of the spool to the right and the spool moves to the left against the spring force.

The slug reduces the effective area on which the oil pressure can push. Because of the reduced effective area, a smaller, more sensitive spring can be used. Pilot pressure will be equal to the force of the spring on the left end of the spool. The spring force can be adjusted with shims. Pilot pressure is 1725 ± 70 kPa (250 ± 10 psi).

Lockup clutch valve in DIRECT DRIVE

Shown is a sectional view of the torque converter lockup clutch valve in DIRECT DRIVE.

When the lockup solenoid is energized, pilot oil moves a shuttle valve to the right, which closes the lower left drain passage and opens the check valve. Oil then flows to the selector piston. Moving the selector piston blocks the upper drain passage, and the load piston springs are partially compressed.

When the load piston that compresses the springs is at the top against the selector piston, lockup clutch pressure is at its lowest controlled value. This value is called "primary pressure." Primary pressure is 1030 ± 35 kPa (150 ± 5 psi).

As the load piston moves down, the lockup clutch pressure increases gradually until the load piston stops. The final lockup clutch pressure is then reached. The final (maximum) lockup clutch pressure should be 2135 ± 70 kPa (310 ± 10 psi). The gradual increase in pressure, which depends on how fast the load piston moves, is called "modulation."

The speed of the load piston movement depends on how fast the oil can flow to the area above the load piston. The load piston orifice meters the flow of oil to the load piston chamber and determines the modulation time.

The primary pressure is adjusted with shims in the load piston. The final lockup clutch pressure is not adjustable. If the primary pressure is correct and the final lockup clutch pressure is incorrect, the load piston should be checked to make sure that it moves freely in the selector piston. If the load piston moves freely, the load piston springs should be replaced.

Converter hydraulic system with caliper disc front brakes

This schematic shows the flow of oil from the torque converter pump through the torque converter hydraulic system on the 777D Update truck with caliper disc front brakes.

The scavenge pump section pulls oil through a screen from the torque converter housing and sends the oil to the hydraulic tank.

The charging pump section sends oil through the torque converter charging filter to the torque converter inlet relief valve. Oil flows from the inlet relief valve through the torque converter to the outlet relief valve. Oil flows from the outlet relief valve through the torque converter oil cooler to the rear brakes.

The parking brake release pump section sends oil through the parking brake release filter to the parking brake release valve and the torque converter lockup clutch valve. Most of the oil flows through the parking brake release valve and the torque converter oil cooler to the rear brakes.

Converter hydraulic system with oil cooled front brakes.

This schematic shows the flow of oil from the torque converter pump through the torque converter hydraulic system on the 777D Update truck with oil cooled front brakes.The scavenge pump section pulls oil through a screen from the torque converter housing and sends the oil to the hydraulic tank.

The charging pump section sends oil through the torque converter charging filter to the torque converter inlet relief valve. Oil flows from the inlet relief valve through the torque converter to the outlet relief valve.

Oil flows from the outlet relief valve through the torque converter oil cooler to the rear brakes.

The parking brake release pump section sends oil through the parking brake release filter to the parking brake release valve and the torque converter lockup clutch valve. Most of the oil flows through the parking brake release valve and the brake oil cooler to the front and rear brakes. The brake cooling pump section of the torque converter pump (oil cooled front brakes only) sends additional oil through the torque converter oil

cooler located on the right side of the engine to the rear brakes.

Transmission and Transfer Gears

Power flows from the torque converter through a drive shaft to the transfer gears (1). The transfer gears are splined to the transmission input shaft.

The transmission (2) is located between the transfer gears and the differential (3).

The transmission is electronically controlled and hydraulically operated as in all other ICM (Individual Clutch Modulation) transmissions in Caterpillar rigid frame trucks.

The transmission is a power shift planetary design which contains seven hydraulically engaged clutches. The transmission provides seven FORWARD speeds and one REVERSE speed.

The differential is located in the rear axle housing behind the transmission. Power from the transmission flows through the differential and is divided equally to the final drives in the rear wheels. The final drives are single reduction planetaries.

Transmission Hydraulic System

The two section transmission pump is mounted on the rear of the pump drive, which is located inside the right frame near the torque converter.

The two sections are:

* Transmission scavenge (1)

* Transmission charging (2)

The transmission scavenge section pulls oil from the bottom of the transmission case through the magnetic screen located below the cover (3). The magnetic screen should always be checked for debris if a problem with the transmission is suspected.

The scavenged oil from the transmission flows through the transmission oil cooler and returns to the transmission tank.

The transmission charging section pulls oil from the transmission tank.

Charging oil flows from the pump through a transmission charging filter to the hydraulic controls in the transmission.

Transmission charging filter

Oil flows from the charging section of the transmission pump to the transmission charging filter (1) located on the frame behind the right front tire.

Oil flows from the transmission charging filter to the transmission control valve located on top of the transmission.

Transmission oil samples can be taken at the Scheduled Oil Sampling (S.O.S) tap (2). An oil filter bypass switch (3) is located on the filter. The oil filter bypass switch provides an input signal to the Caterpillar Monitoring System, which informs the operator if the filter is restricted.

Transmission control valve supply port

The transmission charging pump supplies oil to the transmission hydraulic control valve and the shift solenoids through the inlet port (1). Excess transmission charging oil drops to the bottom of the housing to be scavenged.

The transmission hydraulic control valve contains a priority valve. The priority valve controls the pilot pressure that is directed to the selector pistons in each of the clutch stations. The pilot pressure is 1720 kPa (250 psi) and can be measured at the plug (2).

The transmission charging pressure relief valve is part of the transmission hydraulic control valve. The relief valve limits the maximum pressure in the transmission charging circuit. Transmission charging pressure can be measured at the tap (3). At LOW IDLE in TORQUE CONVERTER DRIVE, transmission charging pressure should be 2480 kPa (360 psi) minimum. At HIGH IDLE in TORQUE CONVERTER DRIVE, transmission charging pressure should be 3200 kPa (465 psi) maximum.

Shown is the Individual Clutch Modulation (ICM) transmission hydraulic control valve. Transmission clutch pressures are measured at the pressure taps (4).

The transmission lube pressure relief valve (5) limits the maximum pressure in the transmission lube circuit. The lubrication oil is used to cool and lubricate all of the gears, bearings and clutches in the transmission and transfer gears.

Transmission lube oil pressure tap (arrow)

The transmission lube pressure relief valve is in the transmission case on the transmission hydraulic control valve (see previous slide). The relief valve limits the maximum pressure in the transmission lube circuit.

Transmission lube oil pressure can be measured at the tap (arrow) on top of the transfer gear case.

At LOW IDLE, the transmission lube pressure should be 3 to 41 kPa

(.5 to 6 psi). At HIGH IDLE, the transmission lube pressure should be 83 to 138 kPa (12 to 20 psi).

Transmission in NEUTRAL

This schematic shows the conditions in the system with the ENGINE STARTED and the transmission in NEUTRAL. The priority reduction valve is installed in the bore on the left side of the valve body. This valve has two functions: It controls the pressure of the pilot oil (orange) that is used to initiate clutch engagement, and it makes sure that pilot pressure is available at the neutralizer valve before pressure oil (red) is sent to the

remainder of the system.

The neutralizer valve moves only when the rotary selector spool is in the NEUTRAL position. When the rotary selector spool is in the NEUTRAL position and the engine is started, pump oil flows through a passage in the center of the neutralizer valve, flows up around the check ball, pressurizes the top of the valve, and then moves down. In this position, the neutralizer valve directs pilot oil to the center of the rotary selector spool.

If the rotary selector spool is not in the NEUTRAL position during engine start-up, the neutralizer valve will block the flow of pilot oil to the rotary selector spool.

Directly below the neutralizer valve is the main relief valve. This valve limits the maximum system pressure during operation. Excess pump oil is directed to the lubrication circuit and the pressure is maintained by the lube relief valve. The lubrication oil is used to cool and lubricate all of the gears, bearings and clutches in the transmission and transfer gears.

To initiate a shift, pressure oil from either the upshift or downshift solenoid is sent to the rotary actuator. Inside the actuator housing is a rotating vane which divides the actuator into two chambers. Pressure oil from the upshift solenoid causes the vane to rotate in one direction while pressure oil from the downshift solenoid causes the vane to rotate in the opposite direction. The vane is connected to and causes rotation of the rotary selector spool inside the selector valve group.

The transmission hydraulic system is equipped with a two section gear pump. From the charging section of the pump, the oil flows through the filter and is sent directly to the two solenoids and the selector valve group. Pump flow is blocked at the upshift solenoid and, because the downshift solenoid is continuously energized in NEUTRAL, the valve in the solenoid is open. This condition permits oil to flow to the rotary actuator.

Pressure on the downshift side of the rotating vane in the rotary actuator keeps the vane and the rotary selector spool in the NEUTRAL position until a shift is made.

The rotary selector spool is actually a hollow rotating shaft. A plug and screen assembly inside the spool divides the center cavity into two separate oil chambers.

During operation, pilot oil from the upper chamber is directed to the pressure control valve group to initiate clutch engagement. For any gear except NEUTRAL, two of the outlet ports from the upper chamber are aligned with drilled passages in the selector valve body. For NEUTRAL, only one outlet port permits pilot oil to flow to the pressure control valve group.

The lower chamber in the rotary selector spool is always open to drain. For each gear position except NEUTRAL, all but two of the drain ports are open to drain. Whenever a clutch station is engaged, the lower half of the spool blocks the drain passage to that station. All oil that is in the bottom of the transmission case is returned to the tank by the transmission scavenge section of the transmission pump.

Fourth speed FORWARD

This schematic shows the components and the oil flow in the system during operation in FOURTH GEAR. The upshift solenoid is energized and directs pump oil to the rotary actuator. The rotary actuator moves the rotary selector spool to the FOURTH SPEED FORWARD position and the upshift solenoid is de-energized. The rotary spool selects two stations (C and E) which modulate the two clutches.

To shift from NEUTRAL to any other gear, the rotating vane must turn in the clockwise direction to the selected gear position. When the shift is indicated, pressure oil from the upshift solenoid is sent to the lower inlet port. The pressure oil moves the check valve toward the center of the actuator housing until the check valve covers a drain passage located near the inner end of the inlet passage. The pressure oil then flows through the

check valve and fills the small space between the two vanes.

As the pressure increases, the rotating vane moves in the clockwise direction to the appropriate gear position. Any oil that was in the chamber on the nonpressurized (downshift) side of the vane is forced out of the chamber by the movement of the vane.

As the oil flows out of the chamber, it moves the upper check valve away from the center of the actuator housing.

This movement opens a drain passage located near the inner end of the upper check valve passage and permits the oil to flow out of the center chamber. The check valve closes and prevents oil from flowing to the other solenoid.

This sequence is just the opposite for downshifts (when the rotating vane moves in the counterclockwise direction).

All stations contain same basic components

Since all seven valve stations contain the same basic components, an explanation of the operation of one station can be applied to the operation of the remaining six stations (including the lockup clutch station).

The seven stations that control the clutches contain load piston orifices (sometimes called "cascade" orifices). The load piston orifices control the clutch modulation. The thicker the orifice, the faster the modulation. The retaining springs for the load piston orifices are identical, but the orifices vary in thickness from one station to another. Many of the stations are equipped with decay orifices. Check the parts book for proper component placement.

In this schematic, the engine has been started, but the clutch for this station has not been engaged. While the engine is running, pump (or system) pressure is always available at the modulation reduction valve spool; but, until pilot oil from the rotary selector spool is sent to the right (outer) end of the selector piston, there can be no valve movement and the clutch cannot be engaged.

Station showing beginning of modulation

This schematic shows the relative positions of the valve station components at the start of modulation before the clutch is fully engaged (primary pressure). Valve movement is initiated when pilot oil from the rotary selector spool moves the selector piston to the left as shown.

Movement of the selector piston accomplishes two purposes:

1. The drain passage at the decay orifice is blocked.

2. The load piston springs are compressed.

Compressing the load piston springs moves the reduction valve spool to the left against the force of the inner spring. This movement opens the supply passage (from the pump) and permits pressure oil to flow to the clutch. As the clutch fills, pressure oil opens the ball check valve and fills the slug chamber at the left end of the reduction valve spool. At the same time, oil flows through the load piston orifice and fills the chamber between the end of the load piston and the selector piston.

The load piston orifice provides a pressure drop and time delay in the flow of oil to the load piston chamber. This condition helps control the rate of modulation. Filling the load piston chamber is made possible when the selector piston covers the drain passage at the decay orifice.

The clutch pressure and the pressure in the slug chamber increase at the same rate. Just after the clutch is filled, the pressure in the slug chamber moves the reduction valve to the right. This movement restricts the flow of pressure oil to the clutch and briefly limits the increase of clutch pressure. The pressure in the load piston chamber then moves the load piston farther to the left. This movement increases the spring force and reopens the supply passage permitting the clutch pressure to again increase.

This cycle continues until the load piston has moved completely to the left

(against the stop). The clutch pressure is then at its maximum setting.

During modulation, the reduction valve spool moves left and right while

the load piston moves smoothly to the left.

Modulation cycle completed

The load piston has now moved completely to the left against the stop.

The modulation cycle is completed and the clutch pressure is at its maximum setting. Because this is a modulation reduction valve, the maximum pressure setting of the clutch is lower than the system pressure. At the end of the modulation cycle, the pressure in the slug chamber moves the reduction valve a small distance to the right to restrict the flow of supply oil to the clutch. This is the "metering position" of the reduction

valve spool. In this position, the valve maintains precise control of the clutch pressure.

During operation, an engaged clutch is designed to leak a relatively small but steady volume of oil. This leakage helps prevent high oil temperatures and provides additional lubrication for the planetary gears and bearings. As clutch leakage occurs, the clutch pressure and the pressure of the oil in the slug chamber will start to decrease. At this point, the load piston springs move the reduction valve spool a small distance to the left to open the supply passage. Pressure oil from the pump again enters the clutch circuit and replaces the leakage. Then, the clutch pressure in the slug chamber moves the spool back to the right thereby restricting the flow of supply oil to the clutch. This metering action continues during the entire time that the clutch is engaged.

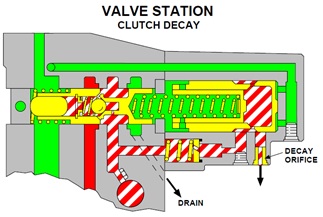

Clutch pressure decreases at controlled rate

During a shift, the pressure of the clutch (or clutches) being released does not immediately drop to zero. Instead, the clutch pressure decreases at a controlled rate. Restricting the rate of clutch pressure decay helps to maintain a positive torque at the transmission output shaft. This feature minimizes the effects of tire and axle "unwinding" and permits smoother shifts. An immediate drop in clutch pressure would permit a rapid

deceleration of the power train components that remain connected to the differential during a shift.

When a clutch is released, the chamber at the right (outer) end of the selector piston is opened to drain through the lower chamber in the rotary selector spool. This condition permits the selector piston and load piston to move to the right as shown. Clutch pressure starts to decrease, but cannot drop to zero until the chamber between the load piston and the selector piston is drained. The only way that oil can flow out of this

chamber is through the decay orifice which was uncovered when the selector piston moved to the right. As the load piston springs force the oil from the load piston chamber, the clutch pressure gradually decreases. When the load piston has moved completely to the right, the clutch pressure is zero.

Modulation cycle of clutches

This graph shows the clutch pressures as the ground speed increases and the transmission shifts into higher gears. Clutch 1 is being gradually released by the controlling effect of the decay orifice. At a certain point, clutch No. 3 is selected and the load piston orifice is controlling the modulation of engagement.

There is some overlap between the decay of the clutch being released and the clutch being engaged. This feature helps to minimize the unwinding motion of the power train and provide smooth shifts.

Initial clutch engagement is the point where the operator can feel the transmission engaging a gear. Complete clutch engagement is the point where the operator feels the clutch stop slipping and the transmission clutch is fully engaged. Clutch pressures continue higher to ensure that the clutches do not slip. Normal clutch slip is the time between initial clutch engagement and complete clutch engagement.

Three shift conditions:

This graph shows the effects of the following conditions:

1. High primary pressure - Shorter engagement time which causes harsh shifts of the power train components and increases the maximum clutch pressure.

2. Low primary pressure - Longer engagement time which causes the plates and discs to slip more before the engagement pressure holds them together. Maximum clutch pressure is also lower and may cause slippage during conditions of heavy loading.

3. Slow modulation - This effect is very similar to the low primary pressure, but it can be caused by a partially plugged load piston orifice. The maximum clutch pressure would be within specifications.

Transmission hydraulic system

The two section transmission pump is mounted on the rear of the pump drive, which is located inside the right frame near the torque converter.

The two sections are:

* Transmission scavenge

* Transmission charging

The transmission scavenge section pulls oil from the bottom of the transmission case through the magnetic screen located below the pump. The scavenged oil from the transmission flows through the transmission oil cooler and returns to the transmission tank.

The transmission charging section pulls oil from the transmission tank. Charging oil flows from the pump through a transmission charging filter to the hydraulic controls in the transmission.

Differential magnetic inspection plug.

Rear Axle

Check the differential oil level by removing the magnetic inspection plug (1). The oil should be level with the bottom of the fill plug opening. The magnetic inspection plug should be removed at regular intervals and checked for metal particles. Inspect the condition of the rear axle breather (2) at regular intervals.

The breather prevents pressure from building up in the axle housing. Excessive pressure in the axle housing can cause brake cooling oil to leak through the Duo-Cone seals in the wheel brake assemblies. A differential carrier thrust pin is located behind the small cover (3). The thrust pin prevents movement of the differential carrier during high thrust load conditions.

Differential

Shown is the differential removed from the rear axle housing. The differential is located in the rear axle housing behind the transmission. Power flows from the transmission to the differential. The differential divides the power to the right and left axle shafts. Torque is transmitted equally from the differential through the two axle shafts to the final

drives.

The differential adjusts the speed of the axle shafts for vehicle cornering, therefore, the power delivered to the axle shafts is unequal during cornering.

The differential thrust pin contacts the differential carrier at the location shown (arrow). When high thrust loads are transmitted from the differential pinion to the differential ring gear, the carrier tries to move away from the pinion. The thrust pin prevents movement of the differential carrier during high thrust load conditions.

THANK YOU FOR YOUR VISITED

POWERTRAIN ON 777D OFF-HIGHWAY TRUCK

Reviewed by heri

on

1:51 PM

Rating:

Reviewed by heri

on

1:51 PM

Rating:

Reviewed by heri

on

1:51 PM

Rating:

Reviewed by heri

on

1:51 PM

Rating:

No comments: