The 793D Mining Truck available in five merchandising arrangements:

• Extended Life Wheel Groups – for long, uphill hauls

• Extra Top Speed – for long, flat hauls

• Extra Retarding – for long, downhill loaded hauls

• High Altitude Arrangement – fo operations above 2750 m (9,000 ft).

Power Train – Engine

The Cat 3516B High Displacement engine is built for power, reliability and efficiency

for superior performance in the toughest applications.

Engine.

The Cat 3516B High Displacement EUI quad turbocharged and aftercooled diesel engine produces 5% greater power with enhanced power management capability for maximum hauling performance in the most demanding mining applications.

Design.

The 3516B is a 16-cylinder, four-stroke design that uses long, effective power strokes for more complete fuel combustion and optimum efficiency.

EPA Compliant.

The Cat 3516B High Displacement engine is compliant with

U.S. Environmental Protection Agency Tier I emissions standards.

Altitude Compensation.

Designed for maximum operating efficiencies at altitudes under 2750 m (9,000 ft).

High Altitude Arrangement (HAA).

The optional Cat 3516B quad and series turbocharged aftercooled short stroke engine provides full power with no deration at altitudes greater than 2750 m (9,000 ft).

High Torque Rise.

The 23% net torque rise provides unequalled lugging force during acceleration, on steep grades and in rough underfoot conditions. Torque rise effectively matches transmission shift points for maximum efficiency and fast cycle times.

Enhanced Life.

High displacement, low rpm rating and conservative horsepower ratings mean more time on the haul roads and less time in the shop.

Single-Piece Piston Design.

New single-piece forged steel pistons with integrated forged steel skirt are more robust to withstand high engine heat and pressure and enable enhanced combustion efficiency, improved

fuel efficiency and lower emissions. Corrosion resistant, stainless steel top ring reduces ring, groove and liner wear for greater reliability and longer life.

Electronic Unit Injection (EUI).

The electronically controlled unit injection fuel system senses operating conditions and regulates fuel delivery for optimum fuel efficiency. The proven high-pressure fuel system provides improved response times and more efficient fuel burn with lower emissions and less smoke.

Electronic Control Module (ECM).

ECM utilizes advanced engine management software to monitor, control and protect the engine utilizing self-diagnosing electronic sensors. The computerized system senses operating conditions and power requirements and adjusts engine for peak performance and most efficient operation and at all times.

Separate Circuit Aftercooler.

Allows the aftercooler circuit to operate cooler than jacket water temperature for a denser air charge and greater combustion efficiency.

Cooling System.

The new modular higher density cooling system with larger fans is hydraulically driven for more efficient cooling with lower fuel consumption and noise levels.

Oil Renewal System.

Optional oil renewal system extends engine oil change intervals from 500 hours to 4,000 hours or more to increase machine availability and reduces costs.

Engine Protection.

Computerized system electronically protects the engine during cold starts, high altitude operation, air filter plugging, and high exhaust temperature.

Power Train – Merchandising Arrangements

Five configurations are performance matched to meet specific applications and conditions.

Merchandising Arrangements.

The 793D is available in four different normal altitude configurations, and a high altitude arrangement. All configurations deliver increased speed on grade and include key components that are performance matched to the hauling application and site conditions.Standard Arrangement.

The standard arrangement is designed for exceptional, all-around performance. Three factors combine to produce up to 9% more power at the wheels than the 793C, including:

5% more engine horsepower; a common rail hydraulic system for greater power train efficiency; and a hydraulically driven demand fan that reduces parasitic load by operating only when needed. More power at the wheels reduces cycle times and lowers cost-per-ton.

Extended Life Wheel Groups.

Developed for uphill hauling applications, this

arrangement is designed to extend wheel life and hauling performance on long uphill hauls. Extended life wheel groups are built with larger, more durable components, including larger spindles, wider wheel bearing spacing, a larger braking surface, and extended life friction disc material for longer brake life and more time between overhauls.

Extra Top Speed. Developed for long, flat haul applications,

the extra top speed configuration delivers a 10% increase in maximum speed to

60 km/h (37 mph) via a new input transfer gear group. This arrangement also includes Extended Life Wheel Groups.

Extra Retarding. Developed for downhill loaded applications this configuration typically

delivers an extra gear of retarding capability of 35% more speed on downhill grades. Extra retarding is achieved by adding more robust wheel groups, larger brakes, extended life friction material, and additional cooling capacity.

High Altitude Arrangement. Developed for high altitude applications, the 3516B short

stroke engine delivers enhanced power management at higher altitudes – from 2750 to 1600 m (9,000 to 12,000 ft).This arrangement also includes Extra Retarding.

Power Train – Transmission

Cat mechanical power train delivers more power to the ground for greater productivity and lower operating costs.

Mechanical Power Train. The Cat mechanical drive power train and power shift transmission provides unmatched operating efficiency and control on steep grades, in poor underfoot conditions, and on haul roads with

high rolling resistance.

1) Transmission. The Cat six-speed planetary power shift transmission is matched with the direct- injection 3516B HD diesel engine to deliver constant power over a wide range of operating speeds.

• Robust Design. Designed for the higher horsepower of the 3516B HD engine, the proven planetary power shift transmission is built tough for long life between overhauls.

• Long Life. A dedicated oil tank and circuit provides cooler, cleaner oil for maximum performance and longer component life.

• Transmission Chassis Control (TCC). TCC uses electronically transferred engine rpm data to execute shifts at preset points for optimum performance, efficiency and clutch life.

2) Lock-Up Torque Converter. Combines maximum rimpull and cushioned shifting of torque converter drive with the efficiency and performance of direct drive. The lock-up torque converter engages at approximately 8 km/h (5 mph), delivering more power to the wheels.

* Lock-Up Clutch. Quickly releases and re-engages to reduce power train torque loads for smoother shifting, long life and a more comfortable ride.

* Smooth Shifting. Individual clutch modulation provides smooth clutch engagements to optimize performance and extend clutch life.

3) Final Drives. Cat final drives work as a system with the planetary power shift transmission to deliver maximum power to the ground. Built to withstand the forces of high torque and impact loads, double reduction final drives provide high torque multiplication to further reduce drive train stress.

• Rear Axle Filtration. A new filtration system provides cooler, cleaner oil for longer component life.

• Steering System. Hydraulic steering control system is designed for exceptional smoothness and precise control. A separate circuit prevents cross contamination for long life.

• Supplemental Steering. Supplemental steering system uses pressure accumulators and allows up to three 90 degree turns in case of engine failure.

• Wheels and Rims. Cast rear wheels and Cat center-mount rims are mounted using studs and nuts to minimize maintenance and maximize durability.

Structures

Rugged Cat structures are the backbone of the 793D mining truck’s durability.

Box-Section Design. The 793D frame uses a box-section design, incorporating two forgings and 24 castings in high stress areas with deep penetrating and continuous wrap-around welds to resist damage from twisting loads without adding extra weight

Steel Structures. Mild steel used throughout frame provides flexibility, durability and resistance to impact loads, even in cold climates, and allows for easy field repairs.

Castings. Castings have large radii with internal reinforcing ribs to dissipate stress in areas of high stress concentration. Castings move welds to lower stress areas for greater frame life.

Integral Four-Post ROPS Cab. Resiliently mounted to the main frame to reduce vibration and sound, the integral ROPS is designed as an extension of the truck frame. The ROPS/FOPS structure provides “five sided protection” for

the operator.

Suspension System. Designed to dissipate haul road and loading impacts for longer frame life and a more comfortable ride.

* Cylinders. Four independent self- contained, oil pneumatic, variable- rebound suspension cylinders are designed to absorb shocks in the most severe applications.

* Durable Design. Rugged cylinders utilize large diameter bore and low pressure nitrogen/oil design for long life with minimal maintenance.

* Front. Front cylinders with preset caster and camber are mounted to the frame and serve as steering kingpins for a tight turning radius with excellent maneuverability and low maintenance

* Rear. Rear cylinders allow axle oscillation and absorb bending and twisting stresses caused by uneven and rough haul roads rather than transmitting them to the main frame.

Engine/Power Train Integration

Electronically combines critical power train components to work more intelligently and optimize overall truck performance.

Cat Data Link. Electronically integrates machine computer systems to optimize overall power train performance, increase reliability and component life, and reduce operating costs

Controlled Throttle Shifting. Regulates engine rpm during shifting to reduce power train stress and clutch wear

by controlling engine speed, torque converter lock-up and transmission clutch engagement for smoother shifts and longer component life

Directional Shift Management. Regulates engine speed during directional shifts to prevent damage caused by

high speed directional changes.

Neutral Coast Inhibitor. Prevents transmission from shifting to neutral at speeds above 6.5 km/h (4 mph) to

protect the transmission from operating with insufficient lubrication.

Body-up Reverse Neutralizer. Automatically shifts the transmission to neutral if the hoist lever is activated while transmission is shifted in reverse.

Programmable Top Gear. Transmission top gear maximum can be set using

the Cat ET service tool to help the operator maintain speed limits.

Anti-Hunt Function. Minimizes shifting by not allowing the transmission to up or down shift immediately after a shift has occurred. This prevents gear hunting when operating near a shift point and minimizes transmission shifting for increased component life.

Downshift Inhibitor. Prevents engine overspeeding by keeping the transmission from downshifting until engine speed reaches the downshift point.

Electronic Technician (Cat ET). Cat ET service tool provides service technicians with easy access to stored diagnostic data through the Cat Data Link to simplify problem diagnosis and increase machine availability

Body-up Shift Inhibitor. Prevents the transmission from shifting above the pre-programmed gear without the body fully lowered.

Overspeed Protection. The transmission control electronically senses engine conditions and automatically up-shifts one gear to prevent overspeeding.

If overspeeding occurs in top gear, the lock-up clutch is disengaged.

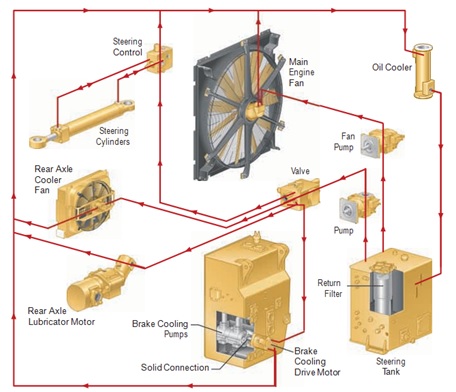

Hydraulic Power Management System

The system, also known as common rail hydraulics, reduces parasitic (unused, wasted) losses in the power management system components and the new hydraulic fan drive system. The system is operated by two new variable displacement piston pumps.These pumps primarily provide for

the steering and cooling functions, and are independent of the brake and hoist circuit. One pump is dedicated to a new on-demand hydraulic fan drive system

The other pump feeds a new priority

valve and provides hydraulic pressure and flow to feed steering, brake cooling, rear axle filtration (RAX), and the optional RAX cooler systems. The system continues to allow priority for the steering system while using an improved power management scheme for brake cooling and RAX functions.

By reducing the losses, the system is able to provide more horsepower to the ground.

Caterpillar Brake System

Reliable braking with superior control gives the operator the confidence to focus on productivity.

Integrated Braking System. The Cat oil-cooled braking system delivers reliable performance and control in the most extreme haul road conditions. The integrated system combines the service, secondary, parking brake and retarding functions in the same robust

system for optimum braking efficiency.

Cat Data Link. All control modules communicate via the Cat Data Link and work together as an integrated system to maximize production efficiency and extend component life.

Oil-Cooled Multiple Disc Brakes. Caterpillar four-wheel, forced oil-cooled, multiple disc service brakes are continuously cooled by water-to-oil heat exchangers for exceptional, non- fade braking and retarding performance.

Extended Life Disc Brakes. Extended life friction material has double the wear life of standard brakes and is twice as resistant to glazing for more consistent braking power with less noise.

Brake Design. Cat oil-cooled disc brakes are designed with large discs and plates for reliable, adjustment-free operation and performance. Brakes are completely enclosed and sealed to prevent contamination and reduce maintenance

Long Life. An oil film prevents direct contact between the discs. This design absorbs the braking forces by shearing the oil molecules and carrying heat away to extend brake life.

Pistons. The Caterpillar two-piece piston design combines the service, secondary, parking brake and retarding functions in the same system. The primary piston hydraulically actuates both service and retarding functions. The secondary piston is spring-applied and held in the disengaged position by hydraulic pressure. If hydraulic system pressure drops below a specified level, the spring-applied secondary piston automatically applies the brakes.

Parking Brake. Oil-cooled, spring- applied, hydraulically released parking brake is applied to all four wheels for superior parking capability on all grades up to 15 percent.

Hydraulic Automatic Retarder Control (HARC). Hydraulically activated automatic retarder control system electronically controls retarding on grade to maintain optimum engine rpm and oil cooling. Additional braking may be applied using the manual retarder or the brake pedal. HARC is deactivated when the operator applies the brake or accelerator controls.

HARC vs. ARC.

• Less chance for engine overspeed

• Smoother engagement

• No loping

• Less air system demand

• Reduces operating costs.

HARC Production Advantages.

Faster Speeds. HARC allows the operator to maintain optimum engine speeds for faster downhill hauls and greater productivity.

Superior Control. Automatic brake modulation offers a smoother ride and better control in slippery conditions, allowing the operator to concentrate on driving.

Ease of Operation. HARC increases operating ease, resulting in greater operator confidence with less fatigue.

Engine Overspeed Protection. Automatically activates HARC when engine speed exceeds factory preset levels, regardless of operator inputs, to avoid potentially damaging engine overspeeds.

Four Corner Retarding. Four corne retarding with 60/40 percent split (rear/front) in braking effort provides superior control in slippery conditions. Balanced front to rear brake torque provides exceptional braking performance and minimizes wheel lock-up, especially during retarding

Traction Control System (TCS). Electronically monitors and controls rear wheel slippage for greater traction and enhanced truck performance in poor underfoot conditions. If slippage exceeds a set limit, the oil-cooled disc brakes engage to slow the spinning wheel. Torque is then automatically transferred to the wheel with better traction.

Differential Action. Normal differential action provides superior maneuvering and control in slippery conditions.

Integrated Braking Control (IBC). Combines Hydraulic Automatic Retarder Control (HARC) and Traction Control System (TCS) into one integrated brake control system for optimum efficiency, performance and reliability.

Fuel Efficiency. The engine provides additional retarding by running against

compression on downhill hauls. During retarding applications the engine ecm does not inject fuel into the cylinders for exceptional fuel economy.

Operator’s Station

Ergonomically designed for operator comfort, superior control and high productivity.

Economic Layout.The 789D operator station is ergonomically designed for total machine control in a comfortable, productive and safe environment.All controls, levers, switches and gauges are positioned to maximize productivity and minimize operator fatigue.

Quiet Cab. Integral, sound-suppressed ROPS/FOPS cab is resiliently mounted to the mainframe to isolate the operator from sound and vibration for a quiet, secure and comfortable ride.

Viewing Area. Designed for excellent all-around visibility and clear sight lines to the haul road, the large viewing area enables the operator to maneuver with confidence for high productivity.

1) Air Suspension Seat w/ Three-Point Operator Restraint. Ergonomically designed, fully adjustable air suspension seat with adjustable armrests provides optimal driving comfort. A wide, retractable 3-point seat/shoulder belt provides a secure, comfortable restraint.

2) Hoist Lever. Four-position, low effort electronic hoist control system with fingertip control is mounted next to the operator’s seat for ease of operation.

3) Secondary Brake Pedal. Conveniently located on the floor for easy operator control

4) Monitoring System. The VIMS system features an easy-to-read display and easy-to-use operator input keypad for precise machine status information

5) Steering Column. Comfort wheel with tilt and telescoping steering provides a comfortable driving position

6) Transmission Console. Ergonomic gear shift lever with backlit gear indicators optimize efficiency.

7) Parking Brake Reset Valve.

Parking brake cannot be released when air system is drained until valve button is reset.

8) Storage Compartment. Located under the trainer seat for a safe, uncluttered working environment.

9) Trainer Seat. Full-size, fully padded trainer seat features a backrest, wide hip and shoulder room, and seat belt for secure travel. Air suspension, optional.

10) Operator Window. Powered operator window and sliding trainer seat window offer simple operation and an unobstructed view.

11) Operator Controls. Easy to reach turn signal, high beam, intermittent windshield wiper and windshield washer controls are designed for optimum efficiency and comfort.

12) Heating/Air Conditioning. Electronically controlled four-speed fan and eleven vents deliver temperature- controlled air circulation for a comfortable working environment in any climate. More robust air compressor offers greater durability and longer life.

Communication Systems Ready.

Cab is prewired with power converter, speakers, wiring harness, antenna and mounting locations for add-on radio, closed circuit TV, and MineStar® systems.

Serviceability

Less time spent on maintenance means more time on the haul roads

Servicing Ease. Easy access to daily service points simplifies servicing and reduces time spent on regular maintenance procedures. Enhanced serviceability and 500-hour service intervals are designed to increase machine availability and productivity.

Maintenance Platform. Provides access to engine, air filters, steering hydraulic tank and battery compartment.

In-Frame Access. Permits easy access to major components for easy servicing and removal.

Ground-Level Access. Allows convenient servicing to tanks, filters, drains, and engine shutdown. Ground-level VIMS data port permits easier downloading

of information.

Transmission Lockout Switch. Ground level transmission lockout switch allows the truck to be serviced with the engine running, without the risk of accidental motion

Autolube. Automatic lubrication system reduces maintenance time by automatically lubricating necessary components on a regular basis.

Fast Fill Service Center. Optional Wiggins fast fill service center features high speed fuel and oil exchange.

Oil Renewal System (ORS). Optional

on-board engine oil management system is designed to increase availability and productivity by extending oil change intervals and reduce oil disposal labor and costs. ORS meters and injects used engine oil from the crankcase into the engine’s fuel return line. New oil is manually added as a part of daily maintenance.

Scheduled Oil Sampling. S•O•S sampling valves speed sampling and analysis reliability

Pressure Test Points. Disconnect valves are conveniently located throughout the hydraulic systems for easy pressure testing.

Air Filters. Radial seal air filters are easy to change, reducing time required for air filter maintenance.

Sealed Electrical Connectors. Electrical connectors are sealed to lock out dust and moisture. Harnesses are braided for protection. Wires are color coded for easy diagnosis and repair.

Cylinder Heads. Individual cylinder heads are interchangeable for easy removal and visual inspection of internal parts.

On-Board Diagnostic Systems.

The VIMS system continuously checks all critical machine functions and components, and helps locate faults quickly for faster repair. Electronic control system enables quick diagnosis of engine conditions and effective maintenance and repairs utilizing the Electronic Technician (Cat ET) service tool.

Mirrors. The left side mirror mounting bracket is more robust and allows mirror glass to be easily replaced, without the need for a new mirror assembly. New mirror glass slides in and out of the carrier, reducing downtime and maintenance costs.

Monitoring System

Vital machine health and payload data keeps the 793D performing at peak production levels.

VIMS Monitoring System. Intelligent Caterpillar designed machine monitoring system provides critical machine health and payload data in real-time to keep the 793D performing at top production levels.

Integrated System Monitoring.

Sensors located throughout the machine systems enable the VIMS system

to quickly exchange and monitor information from all machine systems for efficient, high performance operation.

Advanced Diagnostics. VIMS system simplifies troubleshooting, reduces downtime and lowers operating costs by identifying abnormal conditions before they cause extensive damage.

Data Access. Monitoring and diagnostic information is stored on-board until it can be downloaded for analysis. Data can be accessed through the message center, transmitted via optional radio or downloaded onto a computer for detailed analysis

Machine Management. Service technicians or mine personnel can download data and generate reports for better machine management. Data can be used to improve effectiveness of scheduled maintenance programs, maximize component life, improve machine availability, and lower operating costs

Speedometer/Tachometer Module. Monitors three systems: engine speed, ground speed and gear indicator

Gauge Cluster. Conveniently located gauge cluster maintains a constant display of vital machine functions, including:

• engine coolant temperature

• brake oil temperature

• air system pressure

• fuel level.

Keypad. Provides operator or service technician immediate access to current machine information, gauge values and stored data through the message center display.

Message Center. Displays messages requested by operator and advises operator of abnormal machine conditions

Alert System. Three-category warning system alerts operator of abnormal machine health conditions.

* Category I. Machine or system needs attention

* Category II. Requires operator to evaluate and correct situation before continuing work.

* Category III. Immediate shutdown required to prevent serious damage to machine or system.

Production Management. Production Management enhances truck/loading tool effectiveness, improves fleet productivity and helps extend the life of truck frames, tires, rims and power train components, while lowering operating and maintenance cost

Payload Management. Max Payload Speed Manager is a feature that aids in managing the Caterpillar 10/10/20 Overload Policy. Based on target payload weight and overload settings, the

VIMS system logs and warns the operator when the truck reaches overload after 2nd gear reweigh. The truck will be limited to 2nd gear at 1,750 rpm,

and the automatic retarder speed setting is reduced to 1,750 rpm until the load is dumped.

Payload management enables the manager to enhance truck/loading tool effectiveness and productivity levels by preventing overloads that can cause damage to component life and affect operator safety.

The Payload Weight Distribution chart illustrates the benefit of managing payloads with VIMS production management tools

Data Storage. The VIMS system stores payload information, which is used to manage production. The system stores up to 2,400 production cycles for a complete record of payload weight, cycle times, distances and actual dates/times. It also allows storage of maintenance data such as Events, Trends, Histograms, Cumulatives, Snapshot and Dataloggers. This data allows the user to identify potential problems before they occur, utilizing the efficiency of Preventative Maintenance.

External Payload Indicators. External lights on both sides of the truck signals loading tool operator when to cease loading for optimum payloads without overloading. Optional external payload display with digital numeric monitor are available to replace the standard red/green indicator lamps.

Road Analysis Control (RAC). Optional system monitors haul road conditions by measuring frame rack and pitch to improve haul road maintenance, cycle times, tire life and fuel efficiency.

VIMS-PC. VIMS-PC, the off-board reporting software program, allows service personnel to download a complete record of machine health and productivity data to a laptop computer for diagnosis and analysis. Easy-to-use software enables service technicians and mine personnel to generate health and payload reports for more effective machine management.

VIMS Supervisor. Optional software allows mine personnel to easily manage and interpret VIMS data for optimum fleet management and productivity.

Truck Body Systems

Cat designed and built for rugged performance and reliability in the toughest mining applications.

Cat Truck Bodies. Caterpillar offers three specific body styles and custom body options to help customers obtain the lowest cost-per-ton hauling solution.

• Dual-Slope

• Flat Floor

• Mine Specific Design (MSD II)

Body Selection. Selection of the right body depends on material and haul road conditions. The better the match of body to application, the greater the efficiency. Your Cat dealer can help you select the right body system for your site specific applications

Body/Chassis Integration. Caterpillar truck bodies are designed and matched with the integrated chassis system for optimum structural reliability, durability and long life.

Electronic Hoist Control. Provides the operator with better control of the load when dumping, including over-center load control and modulated control throughout the operating range.

The automatic body snubbing feature reduces impact on the frame, hoist cylinders and operator.

Fast Hoist Cycle Times. Two-stage hoist cylinders provide fast dump cycle times of 20.25 seconds for raise and 17.5 seconds for lower.

Body Liners. A variety of liner options are available to save weight and extend the body system’s life. Wear surfaces and liners are equipped to handle tough impact loads while resisting abrasion. Wear plates deliver long life in high wear areas. Modular liner plate packages:

* Smooth plate

* Rock box

* Zipper grid

* Mechanically Attached Wear Plate System (MAWPS)

Custom Body Options. Tail extensions, sideboards, tumblebars, rock boxes and rock shedders are available to maintain rated payload, reduce spillage, and improve hauling efficiencies.

* Sideboards are designed to maximize or attain gross machine weight.

* Tail extensions are used to help retain the rear portion of the pile and limit load spillage on haul roads, extending tire life

Body Design. Cat truck bodies are designed for optimal strength, capacity and durability. Wear surfaces are equipped to handle even the toughest impact and abrasion over the long haul without diminishing capacity.

* Five-Sided Beams tie in the sidewall and floor junctions add increased body rigidity and strength.

* Wide Ribs in body floor provide increased durability and impact support.

* Full-Length Stringers create strength and rigidity throughout the bed.

* Box Section Beams offer increased durability in the floor, sidewall, top rail, corner, and cab canopy areas.

1) Dual-Slope Body. The dual-slope body design with V-shaped floor provides excellent load retention, maintains a low center of gravity, reduces shock loading, and maintains optimum load distribution on steep inclines and in challenging haul road conditions.

* Reinforced, rolled steel top rail increases body strength and protects the body from damage caused by the loading tool or falling material

* 8 degree “V” reduces shock loading and centers the load.

* 7.5 degree forward body slope and 16 degree ducktail slope helps retain loads on steep grades.

2) Flat Floor Body. The flat floor design with slight incline delivers excellent payload capacity, high dump clearances and smooth, controlled dumping.

* Flat floor design provides consistent wear characteristics on body tail.

* 12 degree forward body slope provides good load retention on better maintained haul roads.

* 400 Brinell steel on surfaces provides excellent wear.

Mine Specific Design (MSD II) Body. The lightweight MSD II body is based on the flat floor design and is customized to maximize payload potential and minimize cost-per-ton. Each MSD II body design begins with a detailed mine site profile to develop a body suitable for a mine’s individual needs.

Target Payload Strategy. Your Caterpillar Dealer can help you manage to target payload to maximize equipment utilization, ensure safe operation, increase productivity and lower cost-per-ton.

* Underloading increases costs due to lost payloads, underutilizes equipment, and drives cost-per-ton.

Overloading or surpassing maximum gross machine weight, causes excessive wear on vehicle components such as brakes, tires and drivetrain, reducing component life and increasing maintenance costs and repairs.

Safety

Caterpillar mining machines and systems are designed with safety as the first priority

Product Safety. Caterpillar has been and continues to be proactive in developing mining machines that meet or exceed safety standards. Safety is an integral part of all machine and systems designs

SAE and ISO Standards. The 793D is designed to many national and international standards.

Integral ROPS Cab. Resiliently mounted to the main frame to reduce vibration and sound, the integral ROPS structure is designed as an extension of the truck frame. The ROPS/FOPS structure provides “five sided protection” for

the operator.

Ladder/Secondary Egress. A wide, stationary stairway allows easy access to and from the machine. The ladder on the left side of the machine permits secondary access or emergency egress.

Brake Systems. Four corner oil-cooled braking system provides excellent control in slippery conditions. The service brakes and retarding system are actuated by modulated hydraulic pressure, while secondary and parking brake functions are spring applied and hydraulic released. This system assures braking in the event of complete hydraulic failure.

Steering System. A twin double-acting cylinder steering system is designed to deliver precise control under all loading and underfoot conditions. The steering hydraulic system is separate from the main hydraulic system to prevent cross- contamination and overheating from other sources.

Engine Shutoff Switch. A secondary engine shutoff switch is located at ground level.

Electrical System Disconnect. A battery disconnect switch, located directly above the front bumper provides ground level lockout of the electrical system

Overload Policy. Safety is integral to maintaining the highest productivity in mining machine operation.

The Caterpillar 10/10/20 Overload Policy assures that steering and braking systems have sufficient capacity to perform, even at 20% overload

Standard Safety Features.

* Slip resistant surfaces

* 75 mm (3 in) wide orange three-point operator restraint

* Wide-angle mirrors

* Body raised indicator

* Body retaining cable

* Guard rails

* Reverse neutralizer when dumping

* Low interior sound level

Dimensions

All dimensions are approximate. Shown with MSD II Body. Dimensions are with Dual Slope Body.

Retarding Performance – Standard

To determine retarding performance: Add lengths of all downhill segments and, using this total, refer to proper retarding chart. Read from gross weight down to the percent effective grade. Effective grade equals actual % grade minus 1% for each 10 kg/t (20 lb/ton) of rolling resistance. From this weight-effective grade point, read horizontally to the curve with the highest obtainable gear, then down to maximum descent speed brakes can properly handle without exceeding.

cooling capacity. The following charts are based on these conditions: 32° C (90° F) ambient temperature, at sea level, with 40.00R57 tires.

NOTE: Select the proper gear to maintain engine rpm at the highest possible level, without overspeeding the engine. If cooling oil overheats, reduce ground speed to allow transmission to shift to the next lower speed range.

Gradeability/Speed/Rimpull.

To determine gradeability performance: Read from gross weight down to the percent of total resistance. Total resistance equals actual percent grade plus 1% for each 10 kg/t (20 lb/ton) of rolling resistance. From this weight-resistance point, readhorizontally to the curve with the highest obtainable gear, then down to maximum speed. Usable rimpull will depend upon traction available and weight on drive wheels.

THANK FOR YOUR VISITED

INTRODUCTION PRODUCT KNOWLEDGE 793 OFF-HIGHWAY TRUCK CATERPILLAR

Reviewed by heri

on

5:19 PM

Rating:

Reviewed by heri

on

5:19 PM

Rating:

Reviewed by heri

on

5:19 PM

Rating:

Reviewed by heri

on

5:19 PM

Rating:

No comments: